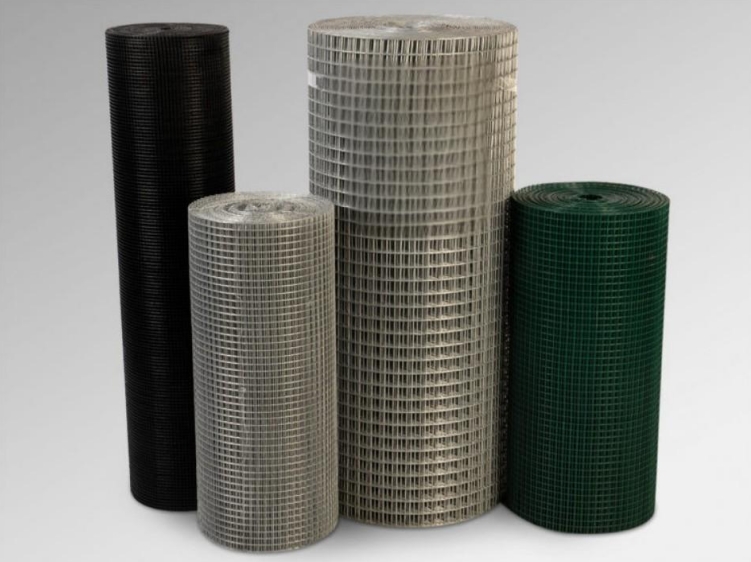

Manufacturing Method: Individual wire mesh bird deterrent are laid vertically and joined together at each intersection using resistance welding.

Construction: Creates a strong grid-like pattern (usually square or rectangular). Welds hold wires securely in place.

Key Properties: High rigidity, dimensional stability, high strength at intersections. Clean edges.

Common Uses: Concrete reinforcement (re-gridding), fence panels, machine guards, caged animals, racking, partitions. Where rigidity and fixed openings are critical.

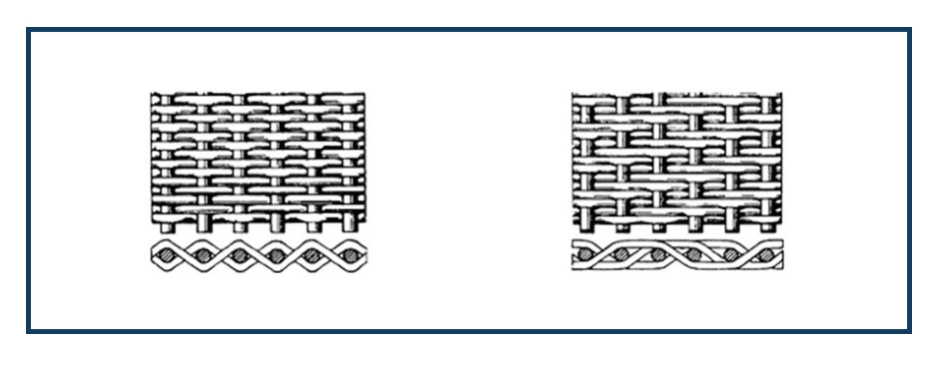

Manufacturing Method: Wires are interwoven up and down on an industrial loom, similar to weaving cloth. Can be plain (simple up and down interweave) or more complex weaves (twill, Dutch).

Construction: Flexible, fabric-like sheet. Wires are not fused, allowing for movement and bending.

Key Properties: Flexibility, drape, good flow characteristics. Cut edges may fray. Available in a variety of weave types to meet specific functions (e.g., filtration, strength, stability).

Common Uses: Window Screens, Insect Screens, Filters (Air, Liquids), Vibrating Screens (Mining/Aggregates), Fencing (Woven Chain Link), Conveyor Belts, Bird Screens. Suitable for applications where flexibility or specific filtering/screening properties are required.

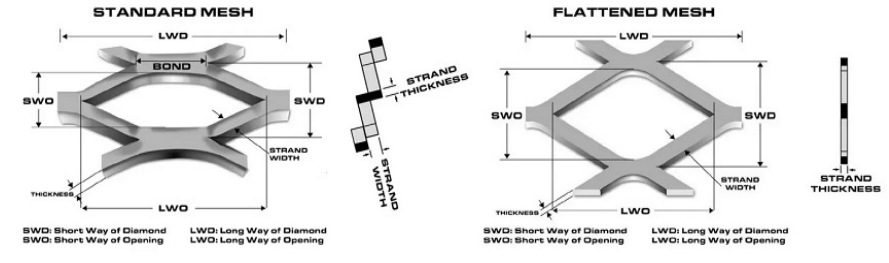

Manufacturing Method: A solid sheet of metal is simultaneously slit and stretched (expanded) on a press at wire mesh fencing factory. This creates a diamond pattern of openings surrounded by the original wires.

Construction: A solid piece of metal with diamond-shaped openings. Characterized by the "wires" (the metal that makes up the sides of the diamond) and the "bonds" (where the wires join).

Key Properties: Lightweight (relative to strength/surface area), good flat rigidity, excellent skid resistance due to raised strands, good ventilation/drainage, very material efficient (no waste). Serrated edges.

Common Uses: Walkways, platforms, stair treads, safety barriers, fences, machine guards, gratings, filtration systems, sunshades. Applications where strength/weight ratio, skid resistance, and ventilation properties are critical.

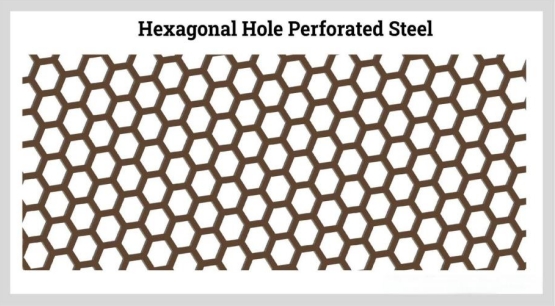

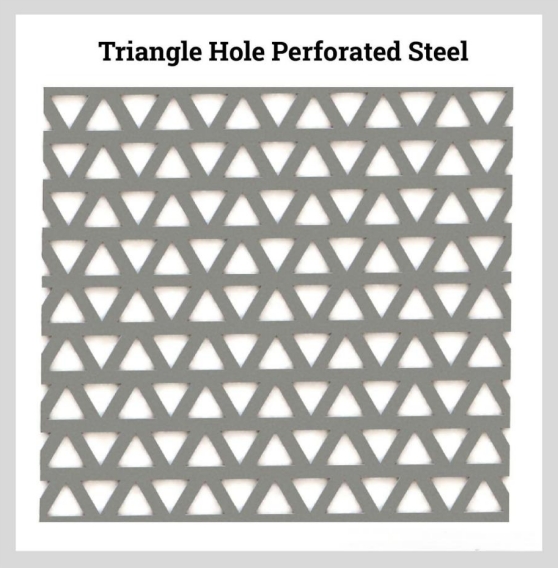

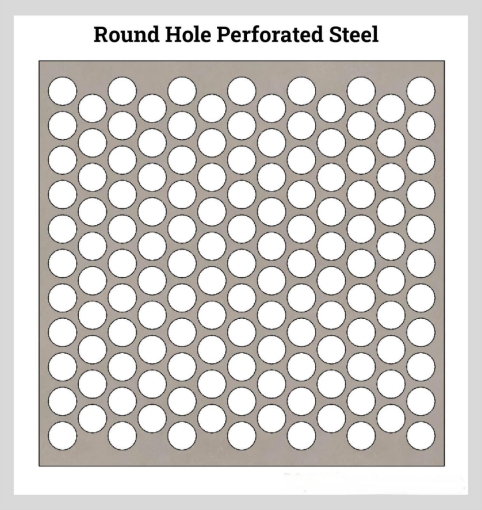

Manufacturing Method: Punches, embosses, or laser cuts holes of specific shapes, sizes, and patterns into solid metal sheet.

Construction: Sheet metal substrate with holes removed. Remaining metal forms pattern.

Key Features: Highly customizable hole shape (round, square, slotted, hexagonal, decorative), precise pattern, aesthetic appearance, good strength (depending on hole size/pattern/material thickness). Material removed as scrap. Edges around holes can be sharp/deburred.

Common Uses: Decorative screens/curtain walls, speaker grilles, filters (coarse), sorting screens, mufflers, machine guards, signs, ventilated panels, acoustic panels. Suitable for applications requiring precise hole pattern, aesthetics, or specific acoustic/flow properties.

Jointed vs. Formed: Welded and braided involve joining wires. Expanded and perforated start from a solid sheet and are formed by opening holes (stretching rather than removing material).

Flexibility: Braided is flexible. Welded and expanded are rigid in a flat surface. Perforated depends on the gauge and pattern, but is generally stiffer.

How to make a hole: Welded/braided creates holes by spacing wires. Expanded creates holes by stretching the material. Perforated creates holes by removing material.

Rigidity and drapeability: Welded is the stiffest. Braided can drape. Expanded is rigid but lightweight. Perforated is as rigid as sheet metal.

Edge treatment: Welded/perforated edges cut cleanly. Braided edges fray easily. Expanded edges are jagged.

Material use: Expanded materials save the most material (no waste). Perforated materials produce waste. Welded/braided uses only wire.