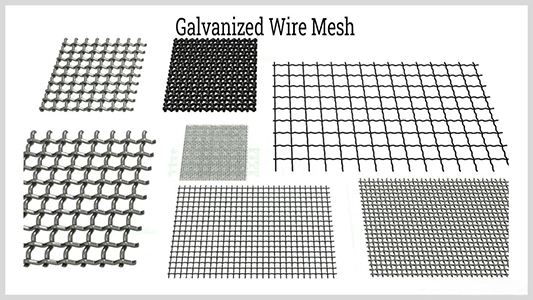

In the industrial warehousing industry, welded wire mesh, woven wire mesh, punched wire mesh and expanded wire mesh have become the core materials for optimizing warehouse management and ensuring operational safety due to their different characteristics.

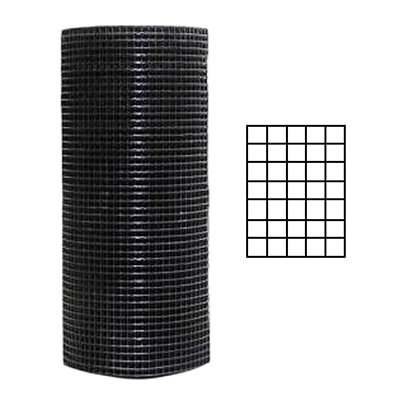

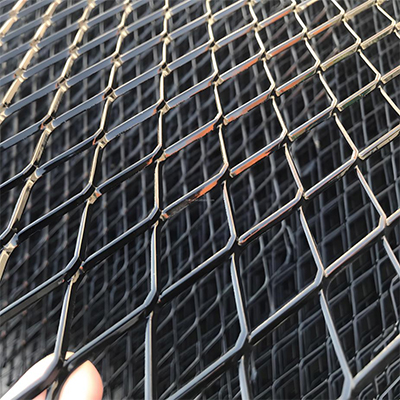

Welded wire mesh forms a stable structure through a solid welding process. It is often used in warehouse shelf guardrails and cargo isolation nets. It can not only carry heavy objects to prevent goods from falling, but also divide storage areas and improve space management efficiency;

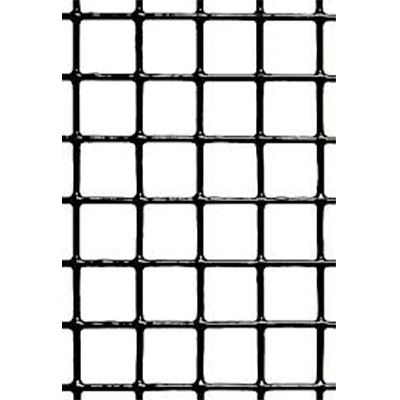

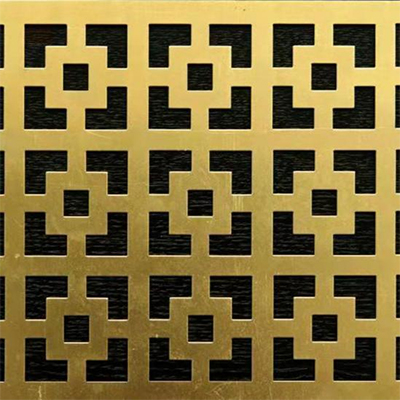

Woven wire mesh is suitable for light cargo classification storage and dust cover nets with uniform mesh and good flexibility. It can accurately isolate different types of goods while preventing dust and moisture;

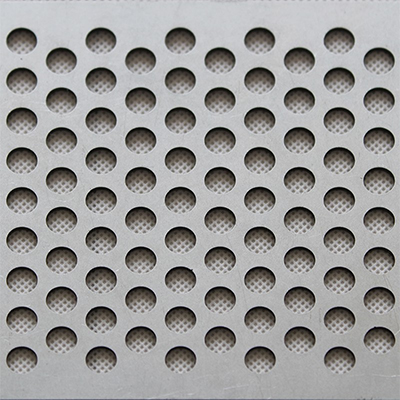

Punched wire mesh can be customized with a variety of hole types and opening rates. It is often used in ventilation equipment protection nets and storage cargo screening platforms. While ensuring air circulation, it ensures safe operation of equipment and realizes efficient cargo sorting;

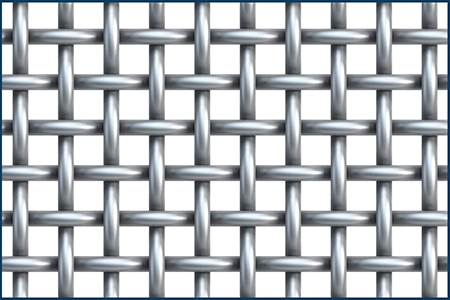

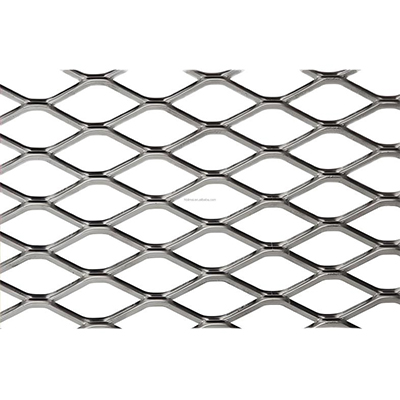

Expanded wire mesh is specially processed to form a high-strength diamond structure with excellent impact resistance and anti-slip performance. It is suitable for heavy equipment protective covers and storage platform anti-slip pedals, effectively resisting equipment collisions and preventing people from slipping. These wire mesh products provide safe and efficient one-stop solutions for the industrial warehousing industry with excellent performance.

If you want to know more about the industrial storage special welding wire mesh, woven wire mesh, punched wire mesh and expanded wire mesh solutions, please contact sales@wiremeshprovider.com

Whatsapp:+8619903282767 to get customized services.