When choosing the right wire mesh product for your project, there are many characteristics to consider. One of the main differences between woven and welded wire mesh is their construction. Woven wire mesh is formed by the cross-over of horizontal and vertical wires.

If the intersection of the wires melts and cools together, the wire mesh is classified as welded wire mesh. However, the differences and functions of these two types of wire mesh go far beyond their manufacturing methods.

Because the seams of welded mesh are connected by welding, it has a certain rigidity and strength. Therefore, it can maintain its fixed open shape even under stress. However, it is important to note that if external pressure exerts too much pressure on the seams of welded mesh, a "breaking point" will occur. At this point, the welded seam may eventually break.

Woven wire mesh

Welded wire mesh

Woven mesh has no fixed connection, so the product is flexible and does not have the rigidity of welded mesh. Because woven mesh does not need to be welded, its flexibility allows it to bend under external pressure and then rebound. These properties make it uniquely durable and useful in practical applications, especially where the strength of the wire mesh is critical.

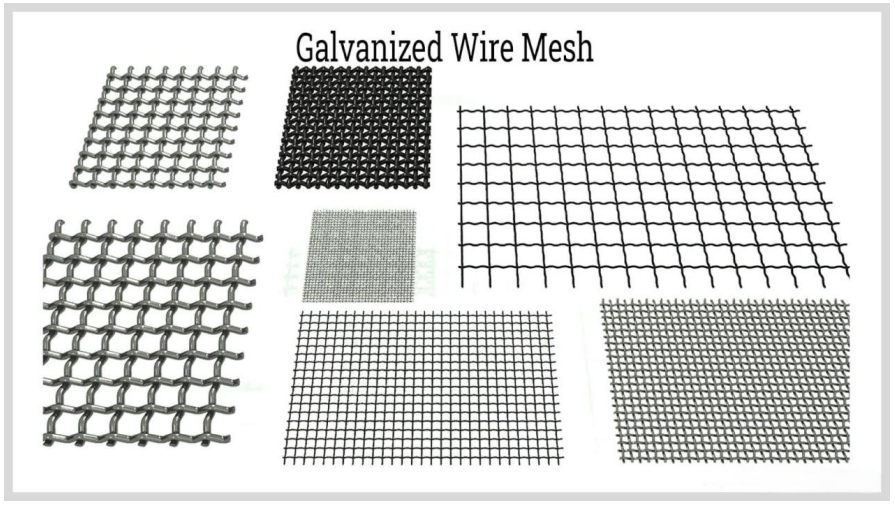

The required opening size is an important factor in determining which type of construction is right for you. Opening size refers to the clearance between wires, measured from the inside edge of one wire to the inside edge of the next adjacent wire. Generally, braided wire has smaller opening sizes, while welded wire is better suited for applications that require larger openings.

For welding, the smaller the opening size required, the smaller the wire diameter must be. This allows for adequate clearance between wires to allow welding. However, if the wire diameter (often referred to as wire gauge) is too small, the heat generated during welding may melt the wire.

For these reasons, the smallest opening size available for welding mesh is usually a 4 x 4 grid (four holes per inch of length measured from the center of the grid). However, some smaller grid sizes are available in stainless steel and PVC coated materials.

It is worth noting that braided wire is generally not suitable for some of the larger opening sizes commonly found in welding products. Braided wire with larger opening sizes may shift and deform because there are no weld points to hold it in place. If you need a braided structure with larger opening sizes, the Snap-On and Center-On braid types offer more rigidity.

Because the braid is not bonded together at every intersection, the wires may break when the material is cut. Larger openings and thinner wires make the braid less rigid. Therefore, once cut, their ends are more likely to unravel slightly.

Some braided meshes come with a selvedge, which is a finished edge. A common way to create a selvedge is to roll up the weft (short) threads and weave them through the warp (long) threads. These looped ends help prevent the mesh from unraveling. Other ways to keep the braid intact include framing the material. Or, for larger openings, a short post can be left to hold the ends in place (although this may be difficult for bias or diagonal cuts).

Snap-On and Center-On braids are more likely to remain intact after cutting. However, they are not permanently secured and may unravel. Since welded mesh is secured at every wire intersection, it is less likely to unravel after cutting.

Wire mesh is available in a variety of materials and finishes, but there are some limitations depending on the type of construction chosen. For example, welded mesh cannot be made with aluminum because it is too soft and the wires tend to melt. Also, while we offer pre-galvanized braided material, braided material is not typically hot-dip galvanized after the wires are braided.

This is primarily because smaller opening sizes (less than 1/4 inch) can become clogged by the zinc oxide solution during the coating process. Additionally, hot-dip galvanizing and powder coating are not suitable for braided fabrics because these processes only coat the wires where they touch each other during the dipping process. In places where the wires overlap or cross, the coating may not be sufficient. When the braided wires are subsequently displaced, the raw or uncoated steel may be exposed to the corrosive elements of the environment.

There are many different factors to consider when determining whether a braided or welded construction type is right for your application. We believe this issue of Hole Stories has shed some light on some of the characteristics of these two widely used mesh types.

If you have any questions or need help deciding which wire mesh product is right for your project, please contact us via Whatsapp +8619903282767 or sales@wiremeshprovider.com, or contact us via Facebook, Instagram, etc.