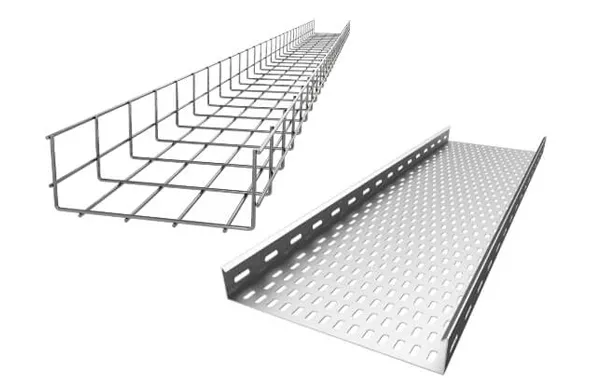

Efficient cable management is essential in modern electrical installations. We offer two high-performance cable tray solutions—perforated cable trays and metal mesh cable trays—designed to provide superior heat dissipation, flexibility, and easy maintenance for your project. Whether it's a data center, commercial building, or industrial facility, we have the right cable management system for you.

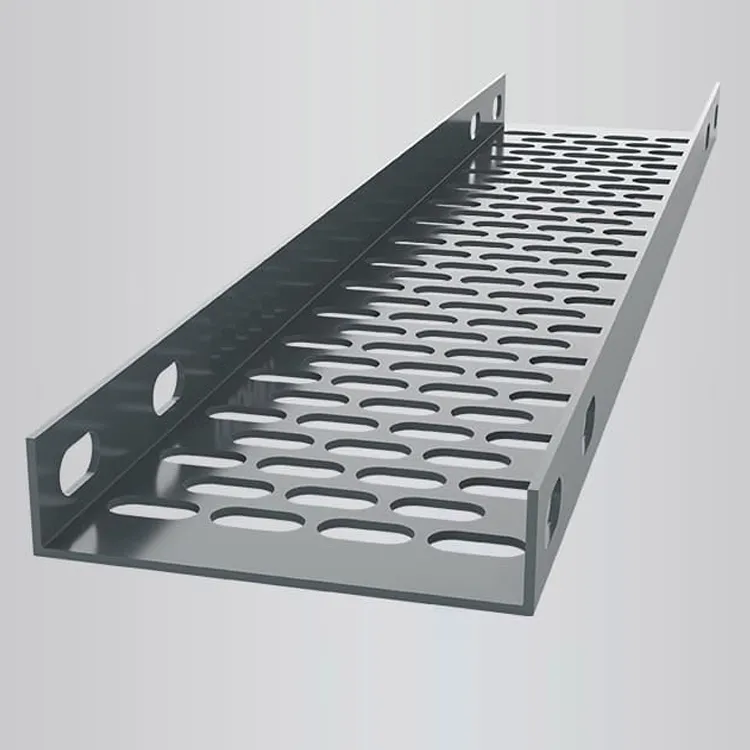

Perforated cable trays are stamped from sheet metal (steel, stainless steel, or aluminum alloy). Their key features are their perforated design and high sidewalls.

Excellent heat dissipation and ventilation: Perforations throughout the tray and cover allow for free air circulation, effectively preventing cable overheating, extending cable life, and preventing excessive accumulation of dust and debris.

Stronger mechanical protection: Compared to metal mesh cable trays, their sidewalls and cover provide better physical protection for cables, preventing accidental mechanical impact and providing a degree of electromagnetic shielding.

Cost-effective: When excellent heat dissipation and mechanical protection are required, perforated cable trays generally offer the most cost-effective solution.

Various material options: Available in pre-galvanized steel, hot-dip galvanized steel, 304/316 stainless steel, and aluminum alloy, they can accommodate a wide range of environments, from standard indoor environments to highly corrosive industrial environments.

Metal mesh cable tray is constructed from high-tensile steel wire welded together to form an open grid structure, resembling a "metal basket."

What are the main advantages of metal mesh cable tray?

Ultimate Openness and Heat Dissipation: The grid structure ensures 360-degree unobstructed airflow, offering the best heat dissipation of all tray types, making it ideal for high-frequency data equipment and server rooms.

Unparalleled Flexibility: The grid structure makes it extremely easy to install, navigating obstacles, varying heights, and complex building structures, making it particularly suitable for renovation projects and ceiling installations.

Ultra-Lightweight and Easy Maintenance: Its extremely low weight significantly reduces loads on the building structure. The open design makes it extremely easy to identify, add, remove, or troubleshoot cables, allowing access from any angle.

Quick Installation and Cost Savings: Due to its lightweight and modular design, installation is typically much faster than traditional trays, saving labor and time.

Each tray has different benefits. Perforated trays offer more continuous support and better protection from dust. Wire mesh trays are lighter, offer maximum ventilation, and are easier to modify on-site.

Our factory commonly uses pre-galvanized steel, hot-dip galvanized steel, stainless steel, and aluminum. Choose the material based on your specific application scenario.

The perforations, or small holes, in the tray allow air to circulate around the cables. This airflow dissipates heat, which prevents the cables from overheating. Proper ventilation extends the cables' lifespan.

Yes, grounding is a mandatory safety requirement for any metal cable management system. Cable trays must be properly bonded and grounded according to national and local electrical codes. Ground jumpers or grounding kits are typically used to connect the cables to ensure a continuous ground path throughout the system, preventing the risk of electric shock in the event of a fault.

Yes, but the tray's finish is critical. For outdoor or corrosive environments, a hot-dip galvanized or stainless steel finish is required. Standard electro-galvanized trays are suitable only for dry, indoor locations. Hot-dip galvanizing provides a thick, durable zinc coating, while stainless steel offers superior rust and chemical resistance.

If you encounter any problems while browsing, please feel free to contact us at any time. We provide you with 7×24 service. In case of emergency, please contact us via email: sales@wiremeshprovider.com