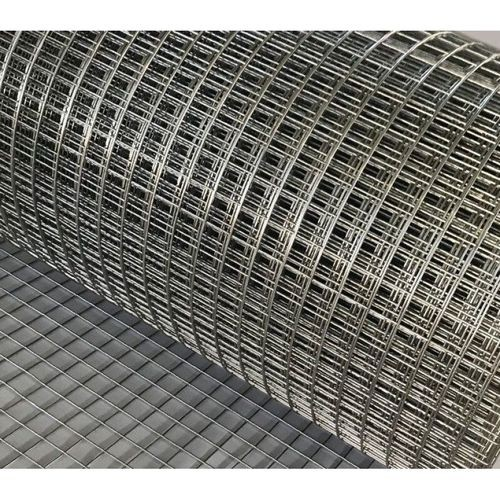

Welded wire mesh rolls, with their solid grid structure, excellent stability, and a wide range of optional materials, have become an indispensable basic material in many fields such as industry, construction, agriculture, and home. Whether you're looking for corrosion resistance or flexibility, options like PVC mesh roll and galvanized welded wire mesh rolls meet diverse application needs. The core technology lies in precisely welding the warp (vertical wire) and weft (horizontal wire) wires at each intersection through resistance welding, forming a strong, flat, and uniform mesh structure.

Hebei Yangzhe Metal Manufacturing Co., Ltd. specializes in the production of high-quality welded wire mesh rolls, providing a variety of material options to meet the stringent requirements of different environments and usage scenarios. As a trusted welded wire mesh manufacturer, YZ ensures these products are delivered in roll form for easy transportation, storage, and on-site cutting.

Material features: High-quality low-carbon steel wire is selected, and after hot-dip galvanizing or electrolytic galvanizing process, a uniform and dense zinc protective layer is formed on the surface.

Core advantages:

Excellent corrosion resistance: The zinc layer provides sacrificial anode protection, effectively resists rust in atmospheric and humid environments, and significantly extends the service life.

High cost performance: While providing good anti-rust ability, the cost is relatively economical, and it is the first choice for wide application.

Good strength and toughness: The base low-carbon steel wire provides reliable mechanical strength and the welding point is firm.

Hebei Yangzhe Manufacturing: We provide hot-dip and electroplating products with different zinc layer thicknesses to ensure that different anti-corrosion grade requirements are met.

Material characteristics: Ordinary low-carbon steel wire (Q195, Q235, etc.) is directly welded and formed, and the surface is usually black oxide scale (so it is often called "black wire mesh").

Core advantages:

Basic strength and low cost: Provide basic mechanical strength and bearing capacity, and it is the most economical choice among all welding meshes.

Processing base material: It is often used as an ideal base material for further surface treatment (such as painting, plastic spraying/plastic coating, hot-dip galvanizing).

Short-term application/indoor application: Suitable for dry indoor environment or occasions with low anti-corrosion requirements and short-term use.

Hebei Yangzhe Manufacturing: Provides bare wire welding mesh rolls with various wire diameters and mesh specifications as the base material for deep processing or specific applications.

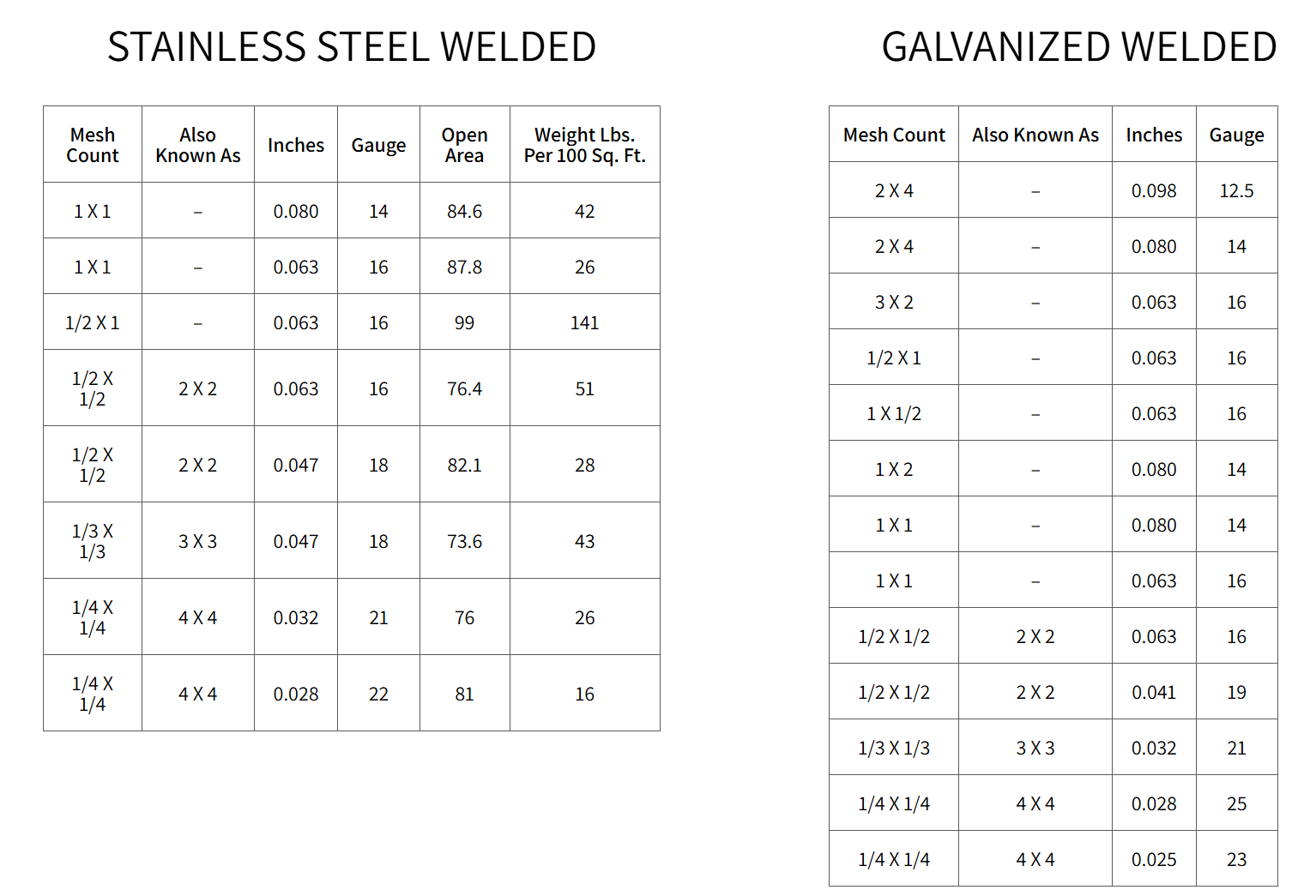

Material features: Made of austenitic stainless steel wire, commonly used grades include:

201 stainless steel: It has a high manganese content and a low nickel content. It has certain corrosion resistance (especially in atmospheric environment) and magnetism. It is cost-effective and suitable for ordinary environments that are not particularly demanding.

304 (06Cr19Ni10): The most common stainless steel grade. Excellent resistance to atmospheric corrosion, water resistance, and corrosion resistance to various chemicals, good formability and weldability, non-magnetic or weakly magnetic. The most widely used.

316 (06Cr17Ni12Mo2): Adding molybdenum (Mo) to 304 significantly improves the ability to resist chloride corrosion (such as seawater, deicing salt, chlorine-containing environment) and pitting and crevice corrosion. Suitable for more stringent chemical, marine, food, pharmaceutical and other environments.

304L / 316L: "L" stands for low carbon content. Better intergranular corrosion resistance, especially suitable for occasions where solid solution treatment cannot be performed after welding or in highly corrosive media environments (such as chemical equipment). After welding, the weld area is not easily sensitized to precipitate chromium carbide, maintaining corrosion resistance.

Core advantages:

Top corrosion resistance: Especially 304, 316 and their L series, they can resist strong oxidizing acids, various organic acids, alkalis, salt solutions, atmosphere, and water vapor corrosion, and almost never rust (under applicable environments).

Excellent high/low temperature resistance: It can maintain good mechanical properties over a wide temperature range.

High strength and hardness: The stainless steel wire itself has high strength and a stable structure after welding.

Hygienic and environmentally friendly: The surface is smooth and easy to clean, and it is not easy to breed bacteria, which meets the hygiene standards of food, medicine and other industries.

Beautiful and durable: The metallic luster lasts for a long time and the service life is extremely long.

Hebei Yangzhe Manufacturing: We strictly select stainless steel raw materials (201, 304, 304L, 316, 316L) that meet the national standard/American standard (AISI) to produce high-quality stainless steel welded mesh rolls that meet different corrosion resistance requirements.

Strong and stable structure: The welding points make the mesh less likely to deform and loosen, providing excellent overall rigidity and load-bearing capacity.

Precise and uniform mesh: The automated welding process ensures consistent mesh size and high precision.

Flat and beautiful: The surface is flat and the edges are neat (burr or folded edge treatment can be provided).

Easy to process and install: Roll packaging is convenient for transportation and storage; it can be cut, bent, and fixed on site as needed.

Diverse choices: In addition to the material, different wire diameters, mesh sizes, widths (common 1m, 1.2m, 1.5m, etc.), lengths (by roll) and surface treatments (such as plastic-coated PVC/PE) are also available.

Long-term economic benefits: Especially galvanized and stainless steel materials, due to their ultra-long life, greatly reduce maintenance and replacement costs.

Industrial protection: machine guardrails, equipment covers, ventilation grilles, work platforms, shelf layer nets.

Building materials: building exterior wall insulation (plastering) nets, floor heating mesh substrates, concrete reinforcement nets (steel mesh), fences, safety protection nets.

Agriculture and animal husbandry: poultry cages, breeding fences, greenhouse frames, seedbed nets.

Warehousing and logistics: shelf interlayers, storage cages, isolation nets.

Home DIY: garden fences, pet cages, storage racks, creative home products.

Filtration separation: some coarse filtration applications (need to be selected according to the mesh size and wire diameter).

Decoration and decoration: stainless steel mesh is used for curtain walls, screens, decorative elements, etc.

All our products support customization, OEM and ODM

304 Stainless Steel Welded Mesh 316 Stainless Steel Welded Mesh

Hot dip galvanized welded wire mesh Electro galvanized welded wire mesh

Plastic Coated Wire Mesh Panels

If you encounter any problems while browsing, please feel free to contact us at any time. We provide you with 7×24 service. In case of emergency, please contact us via email: sales@wiremeshprovider.com