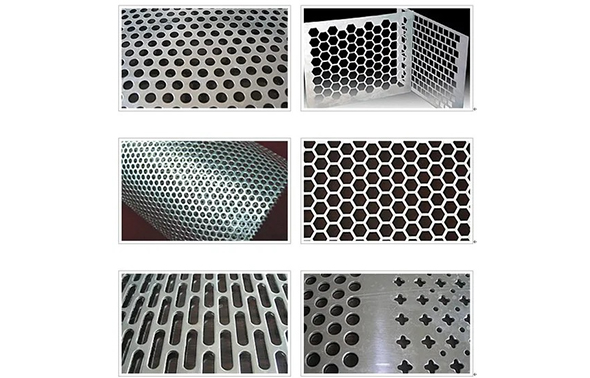

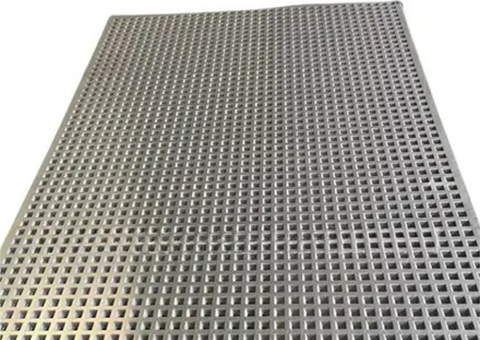

Perforated wire mesh, also known as perforated sheet, perforated plate or perforated screen, is a sheet of metal that has been punched or punched manually or mechanically using CNC technology (sometimes laser cutting) to form holes of varying sizes, shapes and patterns. Materials used to make perforated metal include stainless steel, cold rolled steel, galvanized steel, brass, aluminum, tinplate, copper, monel, inconel, titanium, plastics, etc.

When comparing perforated metal sheet price, factors such as material type, thickness, hole pattern, and order quantity can significantly affect cost. As one of the reliable perforated metal suppliers, we offer competitive pricing, custom fabrication, and fast delivery for a wide range of applications in construction, architecture, filtration, and industrial use.

Perforated metal and expanded metal differ in production, structure, and uses—Yangzhe Wire Mesh Co., Ltd. provides both premium options for diverse needs.

Perforated metal is made by punching precise holes (round, square, hexagonal) into solid metal sheets via presses. It has uniform, consistent openings, high flatness, and retains the base metal’s original thickness, ideal for filtration, decorative panels, and acoustic barriers.

Expanded metal is created by slitting and stretching metal sheets into a diamond - shaped mesh. It has no loose edges, lighter weight (uses less material), and better grip. Its rigid yet flexible structure suits walkways, safety guards, and ventilation grilles.

Choose perforated metal from Yangzhe Wire Mesh for precise filtration/decoration and wire mesh wholesale; pick expanded metal for durable, lightweight load - bearing or anti - slip needs—both meet industrial and architectural standards.

Perforated metal is widely used in architectural design for its blend of functionality, aesthetics, and durability—Yangzhe Wire Mesh Co., Ltd. supplies premium perforated metal tailored to architectural needs.

Its customizable hole patterns (round, hexagonal, geometric) let designers create unique visual effects, from sleek facades to artistic interior panels, boosting a building’s modern appeal. The perforations control light and airflow: filtering harsh sunlight to reduce glare while ensuring natural ventilation, cutting energy use for lighting/AC.

Made from sturdy metals (stainless steel, aluminum) by Yangzhe Wire Mesh, it resists corrosion and weather, suiting outdoor (facades, canopies) and indoor (ceilings, room dividers) use. Also, its lightweight yet rigid structure eases installation. For sustainable, visually striking architecture, perforated metal from Yangzhe Wire Mesh is a top choice.

Perforated sheets can be made from stainless steel, cold rolled steel, galvanized steel, aluminum, copper, brass, titanium, and even certain plastics. The choice depends on the application—stainless steel for corrosion resistance, aluminum for light weight, and brass for decorative appeal.

Typical perforating methods include mechanical punching, CNC punching, laser cutting, and chemical etching. The method is selected based on the hole size, material thickness, production volume, and desired precision.

In most cases, the minimum hole diameter is equal to or slightly smaller than the material thickness. Standard capabilities range from approximately 0.045" (1.14 mm) to 4" (100 mm) in diameter, with material thickness from 0.020" up to 0.5" or more.

Yes. In addition to standard hole patterns, we can produce custom designs, shapes, and brand logos using CNC or laser technology. Special tooling can also be developed for unique patterns.

The cost depends on:

Perforated screen material type and thickness

Hole size, shape, and pattern complexity

Open area percentage

Sheet size and quantity

Finishing processes (flattening, coating, painting, anodizing)

If you encounter any problems while browsing, please feel free to contact us at any time. We provide you with 7×24 service. In case of emergency, please contact us via email: sales@wiremeshprovider.com