Active protection net system:

Tightly cover or wrap the potentially unstable slope surface to inhibit rock loosening, weathering and peeling, and local sliding. High-quality fence mesh for sale can also be applied in such scenarios to enhance surface protection and ensure long-term stability.

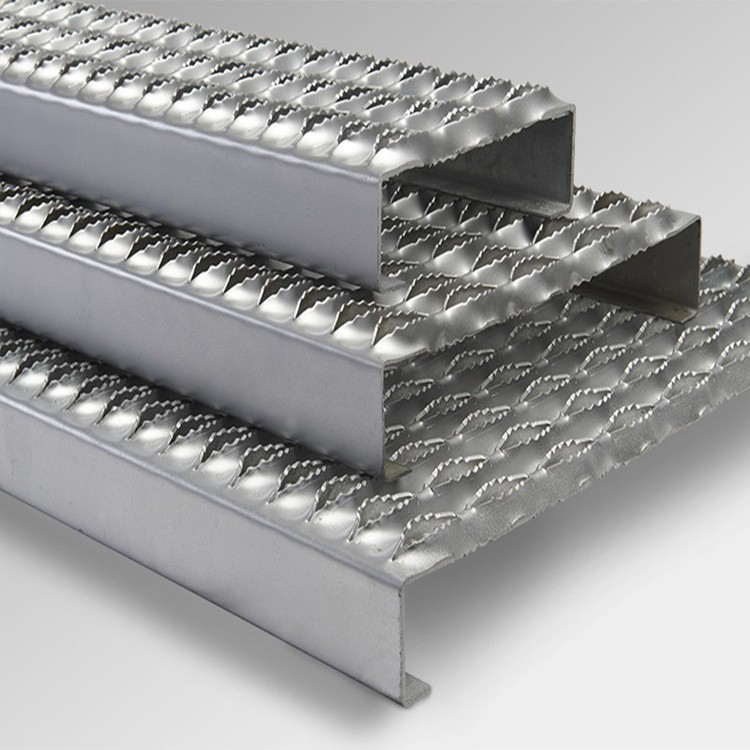

Structure: The main covering layer is usually composed of high-strength steel wire rope net, which is tightened and fixed to the anchor rod (usually with pad) pre-installed on the slope surface through criss-cross support ropes.

Active Protection Net Function

Constrain the loose rock and soil on the slope surface to prevent it from falling or sliding away from the parent body.

Withstand the impact of rockfall and transfer its load to the anchor system and stable strata.

Allow surface water to infiltrate freely and reduce hydrostatic pressure.

Adapt to a certain degree of deformation of the slope without losing the overall protection function.

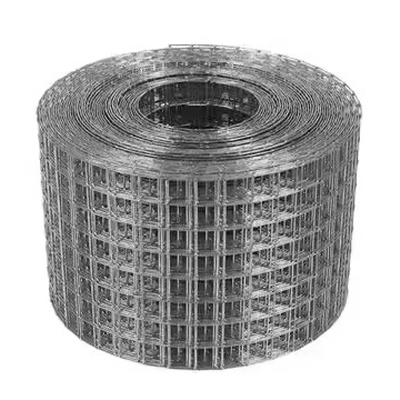

1. Wire diameter: 3mm

2. High tensile strength 1700Mpa

3. Mesh size: 80mm x 140mm

4. Mesh shape: diamond

5. Material: high-strength steel wire

6. Anti-corrosion: plastic coating

7. Coating: 140g/m2

8. Single wire breaking force: 12.5KN

9. Tensile strength: 100KN/m

Standard roll of high-strength anti-falling net:

Mesh edge knotting

Roll width: 2.3m-3.5m

Roll length: 30m-90m

Weight: 1.7kg/m2

Applicable: Weathered and broken rock slopes, soil or soil-rock mixed slopes, and areas where surface instability needs to be suppressed.

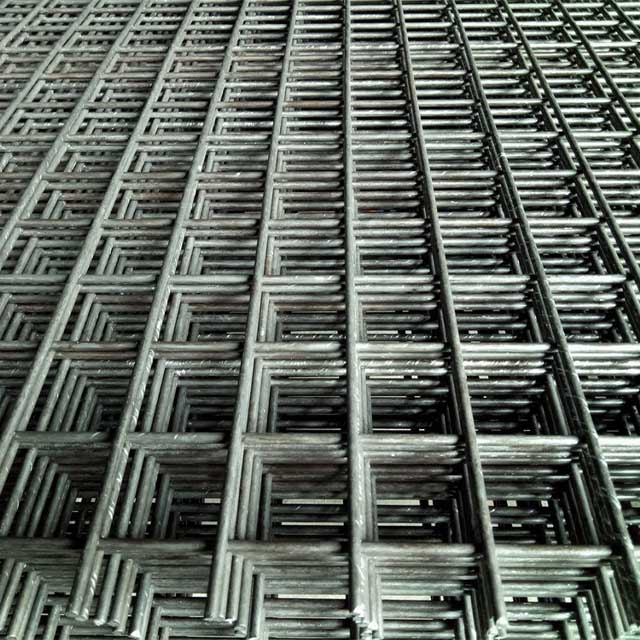

Passive protection net system:

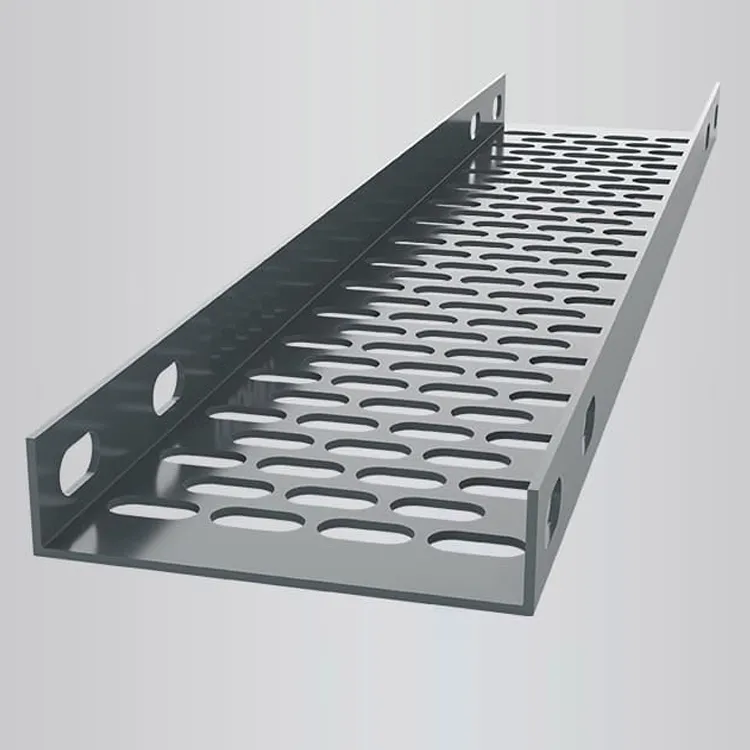

A flexible rock-blocking net wall is set up below the slope or on the rockfall path to intercept and dissipate the energy of the rockfall that has occurred.

Structure: It is mainly composed of steel columns, support ropes, anchor ropes, and wire rope nets. The steel columns serve as the supporting skeleton, the support ropes are tensioned to form a mesh support structure, and the wire rope net serves as the main interception layer. The key decompression ring will deform and elongate when subjected to a huge impact, absorb energy, and protect the entire structure.

Passive Protection Net Function

Intercept and retain rocks and soil blocks rolling down the slope.

Absorb and dissipate the huge impact kinetic energy of the rockfall through flexible deformation.

Transfer the remaining load to the foundation anchor system.

Applicable: Areas located above the slope foot, roads, buildings, pipelines, etc. to intercept the collapse of known or potential rockfall paths.

Key materials: the "bones" of the protective net

The material selection of the core components of the protective net (wire rope, grille wire, ring mesh wire, support rope, etc.) is crucial and directly determines its strength, corrosion resistance, service life and cost. It is mainly divided into three categories:

Low Carbon Steel Wire:

Features: Lowest cost, basic strength can meet general requirements.

Weaknesses: Poor corrosion resistance, very easy to rust and corrode in humid, acid rain, salt spray and other environments, resulting in rapid decline in strength and shortened life.

Application: Mainly used for temporary projects or secondary parts with low requirements for protection life and extremely low environmental corrosion (such as short-term projects in dry inland areas). It should be avoided in permanent projects and highly corrosive environments.

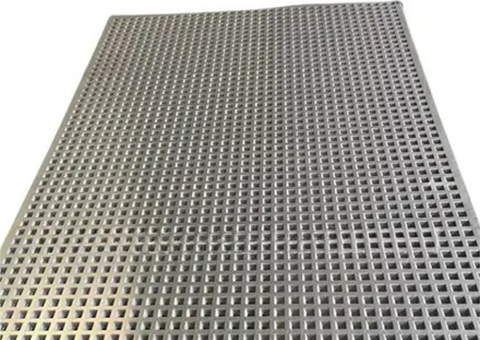

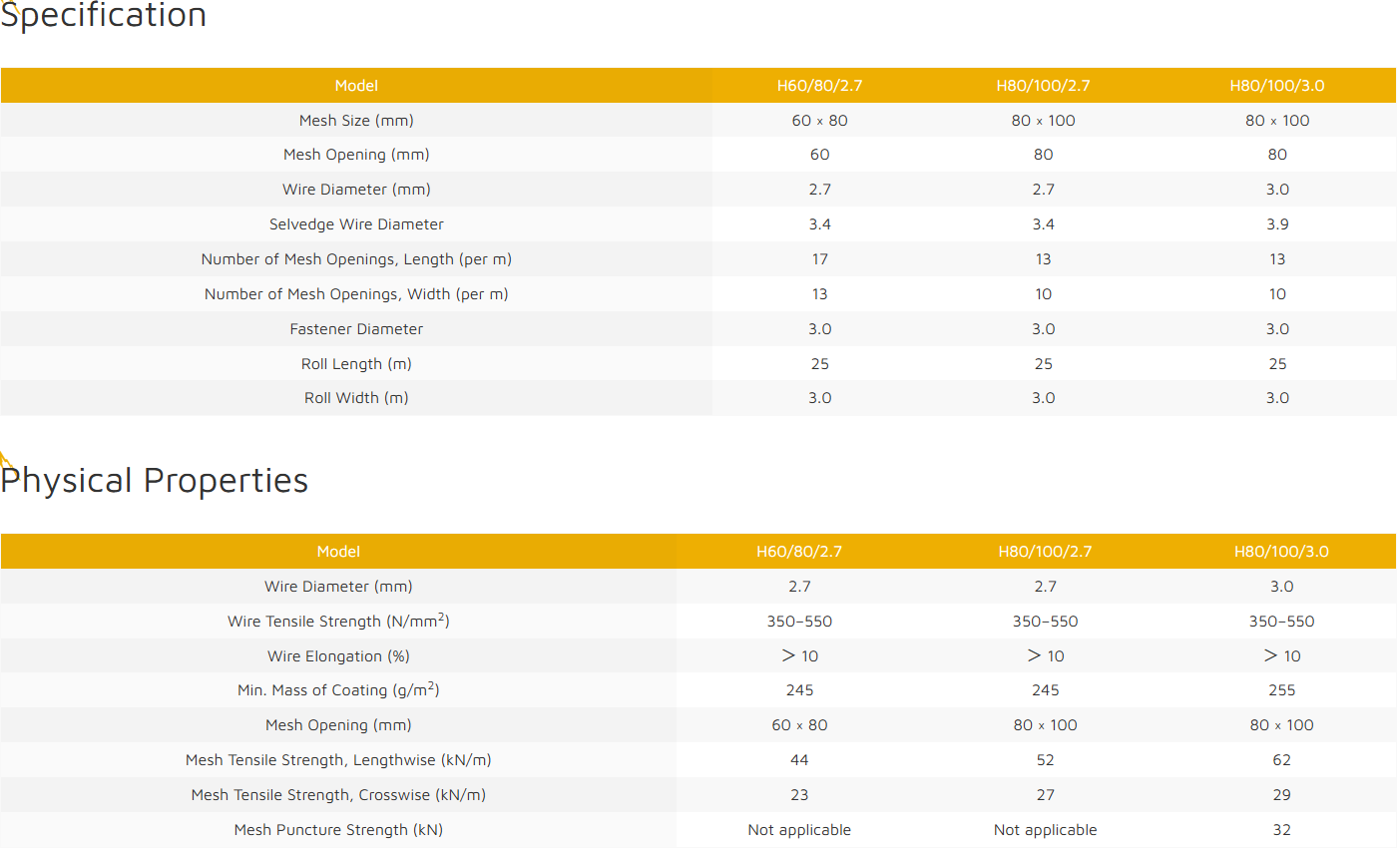

Galvanized Steel Wire:

Features: A layer of zinc is hot-dip plated on the surface of the low-carbon steel wire. The zinc layer provides excellent sacrificial anode protection and significantly improves the steel wire's resistance to atmospheric corrosion. It is cost-effective and is currently the most widely used mainstream material.

Grade: The amount of galvanizing is the key indicator (such as Grade A, Grade B, Grade AB). The higher the amount of galvanizing (such as Grade AB), the stronger the anti-corrosion ability and the longer the service life. Galfan (Zn-5%Al-RE alloy coating) can be used in special environments. Its corrosion resistance and wear resistance are usually better than ordinary hot-dip galvanizing.

Application: The galvanized iron wire mesh is suitable for most slope protection projects and can meet long-term protection needs (the design life can usually reach 30-50 years or longer, depending on the environment and the galvanizing grade).

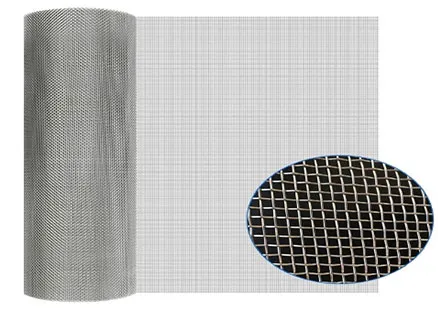

Stainless Steel Wire:

Features: It uses austenitic stainless steel (commonly used 304 or 316 grades).The stainless steel wire mesh stainless steel by YZ wire mesh supplier cloth has excellent corrosion resistance, can resist erosion by strong corrosive media such as acids, alkalis, and salts, and has the longest service life. At the same time, it maintains high strength and good toughness.

Weakness: The cost is the highest, which is several times that of galvanized steel wire.

Application: Mainly used in extreme corrosive environments (such as coastal high salt fog areas, strong acid and alkali industrial areas, hot spring areas), permanent key projects (such as important facilities, bridge tunnel entrances, high-grade highways) or occasions with extremely high maintenance-free requirements. 316 stainless steel contains molybdenum, and its pitting and crevice corrosion resistance is better than 304, and it is more suitable for harsh marine environments.

Wire mesh slope protection nets are an outstanding representative of the concept of flexible protection. Active protection nets are like putting protective clothing on the slopes to actively reinforce the surface; passive protection nets are like setting up an interception dam to passively dissipate the impact of falling rocks. When choosing a protection net, in addition to considering the protection type (active/passive) and structural design, the choice of material (low-carbon steel wire/galvanized wire/stainless steel wire) is the core factor that determines its long-term effectiveness and economy, and needs to be comprehensively weighed according to the importance of the project, design life requirements, environmental corrosion level and investment budget. The correct selection of high-quality protection net systems can build a solid and lasting flexible defense line for our infrastructure and life safety.

Active slope protection mesh Passive slope protection mesh

EN

EN