At Hebei Yangzhe Metal Products Co., Ltd., we have been committed to helping companies accurately match needs and avoid risks with our years of experience in the field of perforated metal. Relying on a large-scale production base and a mature technology system, we are well aware of the core standards for selecting manufacturing partners - whether you need basic perforated panels or complex building components, the key to choosing the right manufacturer is to clarify needs, identify capabilities, and avoid cooperation risks.

Before contacting the manufacturer, clearly defining project requirements is a prerequisite for efficient cooperation. The core needs to clarify the following points:

Material selection and adaptation scenarios

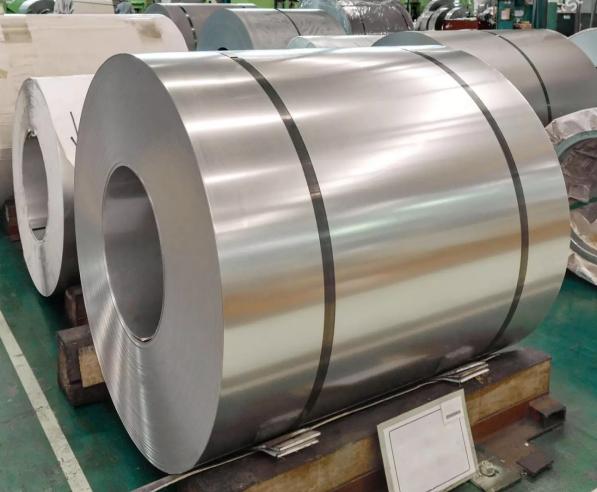

The performance of perforated metal mesh and punching mesh is closely related to the material. Do you need aluminum, stainless steel, carbon steel or brass? Different materials are suitable for different scenarios: Stainless steel perforated mesh is highly corrosion-resistant and suitable for humid or chemical environments; aluminum perforated mesh is lightweight and rust-proof, suitable for weight-sensitive scenarios such as building exterior walls. Hebei Yangzhe specializes in multi-material perforation processing and can recommend the best material solution based on your environmental requirements (such as corrosion and load-bearing requirements).

Copper Coil

Aluminum Coil

Stainless Steel Coil

Clarify production scale and customization needs

Different manufacturers have different areas of strength: some are good at standardized mass production, while Hebei Yangzhe focuses more on perforated metal mesh customization and large-volume order delivery, especially for complex projects that require high-precision details. Whether it is a small sample, medium-volume production or a large-scale engineering order, we can adapt flexibly.

Focus on application scenario details

Application scenarios determine the core specifications of perforated metal mesh: ventilation perforated plates in data centers need to take into account heat dissipation and protection; perforated mesh on building exterior walls needs to balance aesthetics and structural strength; perforated mesh for industrial screening has strict requirements on aperture accuracy and load-bearing capacity. Hebei Yangzhe's technical team will deeply connect with your scenario needs, rather than simply taking orders for production - from environmental adaptability to functional adaptability, all-round guarantee of product implementation effect.

The core competitiveness of excellent perforated metal manufacturers lies in the internal production capacity of the entire chain. Hebei Yangzhe has created a one-stop service system "from perforation to finished product". All processes are completed in its own factory, which means: stricter quality control, faster production turnover, and lower overall cost.

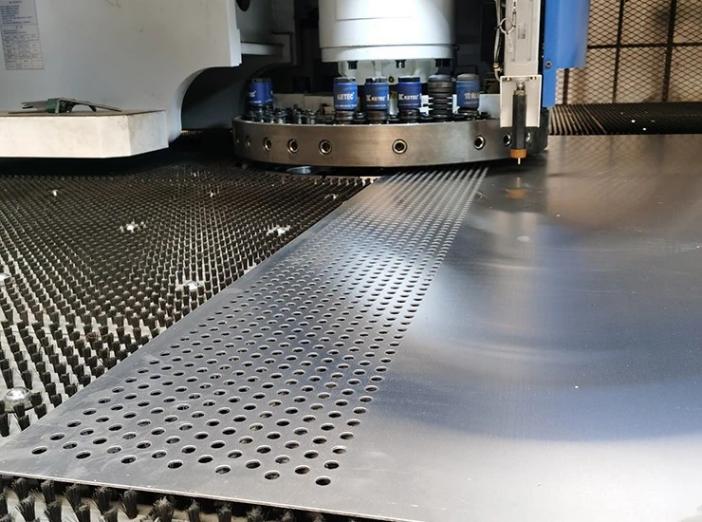

Advanced equipment ensures processing accuracy

We are equipped with multiple high-precision CNC punching machines that can process metal sheets up to 3/8 inches thick and 60 inches wide (special configurations can handle thicker materials), ensuring that the aperture of perforated metal mesh and punching mesh is uniform, the edges are smooth, and the precision error is controlled at the industry-leading level. Whether it is regular round holes, square holes, or special-shaped pattern perforations, they can be accurately achieved.

Full process is self-controlled

From raw material cutting, CNC perforation, to welding and forming, surface treatment (such as galvanizing, spraying), Hebei Yangzhe has achieved full process self-completion, avoiding quality fluctuations and cycle delays caused by outsourcing processing. For architectural decorative perforated metal mesh, we can also provide personalized surface treatment to improve the appearance texture and durability.

Prototyping and trial production support

Before mass production, we provide rapid prototyping services to help you verify the size, performance and installation adaptability of perforated metal mesh, and adjust the optimization plan in time. From conceptual design to final mass production, Hebei Yangzhe's technical team follows up throughout the process and becomes your "problem-solving partner" rather than a simple production executor.

Evaluating perforated metal manufacturers: experience, reputation and details

When choosing a manufacturer, "experience" is not only about years, but also about the ability to implement the project. With years of industry accumulation, Hebei Yangzhe has formed a mature case library covering multiple fields:

Architectural field: customized large-scale exterior wall perforated mesh and interior decoration perforated metal mesh, taking into account aesthetics and structural stability;

Industrial field: production of high-precision screening perforated plates and equipment protection nets, suitable for complex working conditions such as high temperature and corrosion;

Data center / new energy: provide ventilation and heat dissipation perforated mesh to meet strict dustproof, heat dissipation and load-bearing requirements.

10 Quality certification and quality control system

We have passed a strict quality certification system (such as ISO9001). From the storage of raw materials to the delivery of finished products, each process has quality inspection records to ensure the stable and reliable performance of perforated metal mesh and punching mesh.

The "problem-solving ability" of the technical team

Professional manufacturers can not only produce products, but also solve problems. Hebei Yangzhe's technical team is good at providing optimization solutions based on project pain points: for example, for perforated metal mesh of large-span buildings, the weight is reduced while the load-bearing capacity is enhanced through structural design optimization; for outdoor scenes, weather-resistant coatings are recommended to extend the service life. We always aim to succeed in customer projects and provide technical support beyond expectations.

Choose Hebei Yangzhe: Make perforated metal mesh projects more reliable

Whether it is a basic perforated plate or a highly complex customized perforated metal component, Hebei Yangzhe can escort your project with "full-chain capabilities, scenario-based customization, and strict quality control". We are well aware that every perforated metal mesh project carries the trust of customers - from demand communication to final delivery, we carefully control every detail to ensure that your project is efficiently implemented and worry-free in quality.

If you are looking for a professional perforated metal mesh manufacturer, you might as well contact Hebei Yangzhe Metal Products Co., Ltd. and let our team provide you with customized solutions to jointly promote the success of your project!