Chromium, nickel, and molybdenum all play a key role in enhancing the versatility and reliability of stainless steel mesh. The addition of chromium to the steel forms a thin, invisible oxide layer on the wire surface, allowing stainless steel to maintain its renowned resistance to rust and oxidation, even in wet or harsh environments.

Nickel, working together with chromium, not only enhances the corrosion resistance of the wire mesh but also provides additional toughness and flexibility. This makes the wire mesh less prone to cracking or breaking under stress, while maintaining strength at both high and low temperatures—critical for many industrial applications.

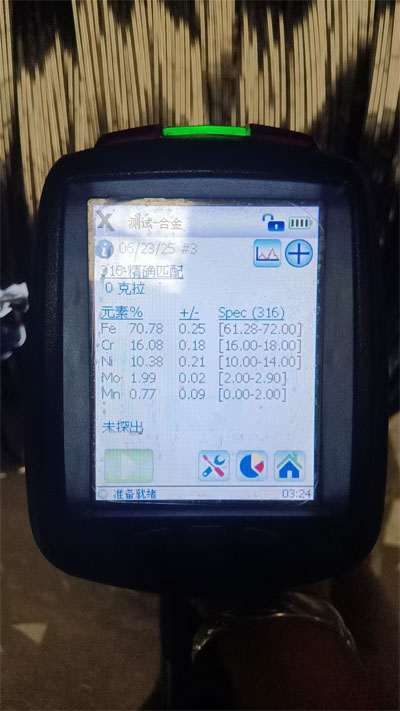

Molybdenum is another beneficial addition, commonly found in grades like 316 stainless steel. It further enhances corrosion resistance, particularly against chlorides, salts, acids, and seawater. This makes molybdenum-containing stainless steel mesh ideal for use in marine, chemical, or highly corrosive environments.

These alloying elements work together to ensure that the stainless steel mesh maintains its structural integrity and long service life, even after repeated cleanings, exposure to chemicals, or extreme conditions.

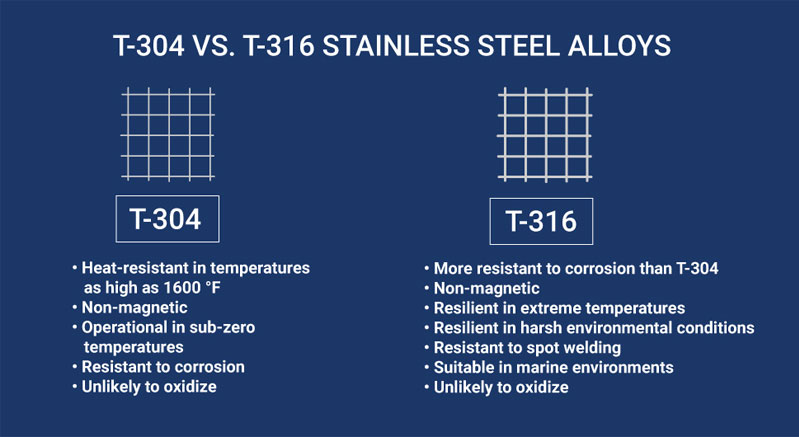

Stainless steel mesh offers exceptional versatility and strength due to its unique chromium-nickel alloy composition. Standard options include T-304 for general use and T-316 for more severe corrosive environments, enabling tailored solutions for diverse industries and applications.

To further meet the specific requirements of your project, we offer a variety of processing and customization services, such as:

Precision Cleaning: Ensures the mesh is free of contamination before use in sensitive environments.

Disc Fabrication: The mesh can be cut into discs suitable for filtration units or custom machinery.

Laser Cutting: Enables smooth-edged complex shapes and sizes, custom-made to unique specifications.

Measuring and Sizing: Provides precise measurements for projects where accuracy is critical.

Slitting: The mesh can be slit into precise widths, ideal for specialized screens and filter components.

Whether you require pre-cut mesh into custom discs, precision-measured, laser-cut, cleaned, or slit, these services help ensure a seamless fit for your application.

For applications like window and door insect screens, certain stainless steel wire meshes are ideal. Finely woven meshes (typically 18 to 30 meshes per inch) are particularly well-suited for keeping insects out while still maintaining good ventilation and visibility.

Popular choices include T-304 stainless steel mesh, known for its rust resistance and strength, and high-visibility mesh, which provides a clearer view without sacrificing insect protection. These meshes are durable and easy to clean, making them a popular choice for homeowners seeking a pest control solution that combines performance with a refined aesthetic.

When choosing insect screen mesh, it's important to consider:

Mesh count: Higher mesh counts (18x18, 20x20, and 30x30) provide greater insect protection.

Wire diameter: Finer wire ensures the screen remains lightweight and less visually impactful.

Corrosion resistance: Stainless steel resists rust, making it ideal for outdoor or humid environments.

By choosing the right gauge, stainless steel insect screens can provide a practical, aesthetically pleasing barrier that will withstand the elements for years to come.

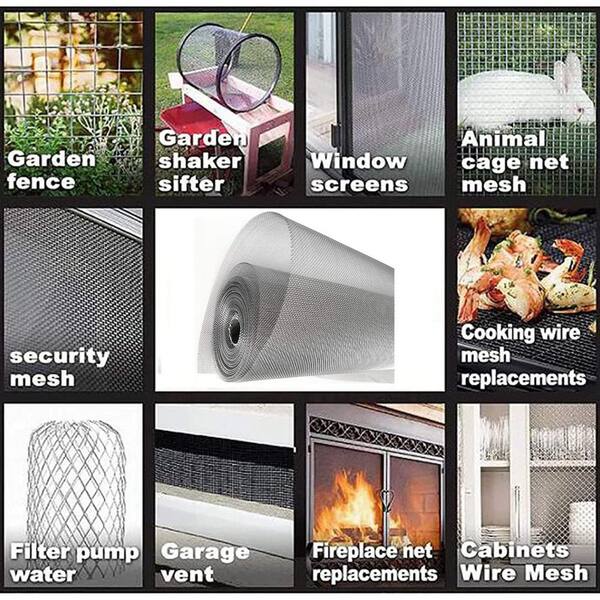

Stainless steel wire mesh isn't just for industrial and manufacturing applications; it's also an incredibly versatile material suitable for a wide range of DIY and home improvement projects. Due to its strength, durability, and rust resistance, homeowners and hobbyists often use stainless steel wire mesh to create practical and creative home solutions.

Some popular applications include:

Home and Garden Projects: Stainless steel mesh is ideal for building sturdy storage racks, pet-proof fencing, and reinforcing cabinets and wall panels. Many gardening enthusiasts use it to create plant stands, compost bins, and durable raised flower beds.

Insect Control: Fine-grained stainless steel mesh can be installed on window frames and doors to act as insect screens. Its tight weave allows air to circulate freely while effectively blocking mosquitoes and other pests from entering the home. High-visibility insect screens are popular for homeowners who want to minimize visual distractions.

Crafts and Custom Lighting: The material is easy to cut and shape, making it suitable for a variety of uses, from creative art installations to custom lampshades. Its sleek metallic appearance adds a modern touch to both functional and decorative projects.

Whether you're looking for something durable for your garden or a stylish solution for your home, stainless steel mesh offers flexibility and reliability for countless DIY projects.

Stainless steel wire mesh is versatile and can be used in both gardening and outdoor projects. In the garden, it's often used to create sturdy fences that keep out rabbits and other pests while maintaining air circulation and views. Stainless steel wire mesh also provides reliable support for plants—whether it's building a trellis for climbing vegetables or a frame to protect young sprouts from strong winds.

For those designing raised beds, stainless steel mesh adds structural strength and helps prevent burrowing animals from entering from below. Gardeners often use fine mesh as a protective barrier for raised beds, protecting seedlings from insects while allowing sunlight and moisture to penetrate. Furthermore, stainless steel mesh is often used in compost bins due to its durability and ability to promote good ventilation.

By integrating these solutions, both amateur and professional gardeners can benefit from the durability, corrosion resistance, and adaptability of stainless steel, making it a staple material for creative and functional gardening applications.

Stainless steel wire mesh offers excellent resistance to acids, alkalis, heat, and corrosion. It is widely used for sorting and screening solids, liquids, and gases in the petroleum, chemical, food, and pharmaceutical processing industries, as well as in mining, metallurgy, aerospace, and machinery manufacturing.

Renowned for its exceptional durability and reliability, stainless steel mesh is a favorite in both heavy industry and precision applications. Its versatility makes it a top choice for a wide range of uses—from industrial filtration and factory screening to DIY projects and gardening solutions. Made from chromium and nickel alloy steel, stainless steel mesh offers unique resistance to rust and wear, enhancing its corrosion resistance. It can also withstand extreme temperatures and harsh environments, remaining strong despite exposure to both high and low temperatures.

Furthermore, stainless steel wire mesh is generally non-magnetic in its annealed state, but may become slightly magnetic after weaving due to cold working. Its notable features include:

Excellent strength and corrosion resistance

Versatility across multiple industries and environments

Wear, rust, and corrosion resistance

Stable performance and long service life

These qualities ensure that stainless steel wire mesh maintains stable, excellent filtration performance, meeting the demanding needs of modern industry and custom user requirements.

Material: SUS304, 304L, SUS316, SUS316L, 310, 310S, SUS302, etc.

Stainless steel woven mesh is primarily manufactured from a range of high-performance alloys, each with specific corrosion resistance, strength, and suitability for different environments.

SUS304 (T-304): The most widely used stainless steel alloy, containing 18% chromium and 8% nickel. While SUS304 is not as corrosion-resistant as higher-grade stainless steels, it offers excellent value for money and is suitable for general industrial use, filtration, and infrastructure applications. SUS316 (T-316): In addition to 18% chromium and 10% nickel, 2% molybdenum is added. This material offers excellent resistance to salt, acid, and seawater. It is commonly used in the marine, chemical, and food processing industries, where strong corrosion resistance is required.

SUS316L (T-316L): Similar to SUS316, but with a lower carbon content, it offers improved corrosion resistance, particularly in high-temperature or chloride-rich environments. This makes it an ideal choice for demanding filtration, laboratory, and marine applications.

304L: A low-carbon version of SUS304, it offers improved weldability and resistance to intergranular corrosion after welding.

310, 310S: High-temperature alloys commonly used in heat treatment and furnace applications.

SUS302: Known for its high strength and flexibility, it is suitable for spring wire and mesh that are subject to frequent bending or movement.

These materials enable stainless steel woven mesh to meet the stringent requirements of industries ranging from petrochemical and food processing to aerospace and marine environments, ensuring long service life and stable performance.