In projects such as construction, home improvement, gardening and animal control fencing, material selection directly affects the project effect and lifespan. Wire mesh and welded wire mesh are commonly used materials. Although they look similar, they have completely different characteristics and uses. Hebei Yangzhe Wire Mesh Co., Ltd. is a professional wire mesh supplier and has been deeply involved in the industry for many years. This article will explain the core differences between the two to help you choose the right material for your project.

1. Composition and core uses: characteristics determine scene adaptation

Wire mesh (including galvanized welded mesh): corrosion-resistant outdoor selection

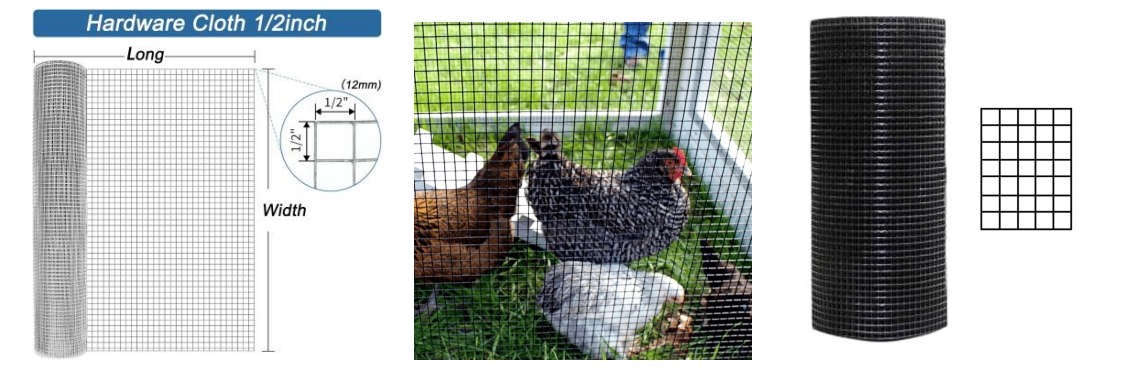

Wire mesh (often called galvanized welded mesh or hardware cloth) is based on metal wire. After galvanizing, the surface has excellent corrosion resistance and can effectively resist wind and rain erosion. It is an ideal choice for outdoor projects. Its core uses are concentrated in:

Gardening scenes: garden fences, vegetable greenhouse insect nets, to prevent pests or small animals from invading;

Farming scenes: insect fences such as chicken coops and rabbit cages, taking into account both protection and breathability;

Outdoor protection: temporary fences for home courtyards, outer protection nets for construction sites, etc.

Compared with traditional wire mesh, the anti-rust properties of galvanized welded wire mesh greatly extend the outdoor service life and reduce maintenance costs.

Welded wire mesh: uniform and stable multifunctional material

Welded wire mesh is a grid structure formed by welding longitudinal and transverse metal wires at precise spacing through a prefabrication process. Hebei Yangzhe provides welded wire meshes of various materials (stainless steel, carbon steel, aluminum, etc.), and its characteristics determine a wider range of application scenarios:

Safety protection: industrial fences, factory isolation nets, and community wall fences require uniform structures to ensure safety;

Structural support: cages, partitions, and equipment protection nets rely on uniform spacing to achieve stable load-bearing;

Decorative scenes: grille filling panels, stair guardrail decorative nets, and neat appearance to enhance aesthetics.

The uniformity and material diversity of welded wire mesh make it outstanding in projects that focus on consistency and strength.

2. Construction process: the connection method determines the performance difference

Wire mesh: the protective advantage of tight connection

The construction of wire mesh is centered on "tightness". Single wires are connected through weaving or welding processes to form a fine and elastic mesh. This structure allows the wires to fit tightly together with extremely small gaps, which can effectively prevent small pests, mice, etc. from penetrating, and has better protection performance. According to the thickness of the wire diameter, wire mesh is mainly divided into two types: medium and coarse, which are suitable for different protection strength requirements.

Welded wire mesh: uniform and stable welding

Welded wire mesh uses professional welding technology to weld and fix the longitudinal and transverse wires at the intersection to form a mesh with uniform spacing and solid structure. The welding point has high welding strength and is not easy to loosen, ensuring that the mesh maintains a neat shape for a long time and will not be deformed or the gap becomes larger due to external force. This process makes welded wire mesh more advantageous in scenes that require uniform appearance and heavy loads, such as large fences or equipment protection nets.

3. Customization and size: flexible adaptation to project requirements

Wire mesh (hardware cloth): both standard and customization

As a commonly used hardware cloth, the conventional specifications of wire mesh are mainly in rolls, with a width ranging from 2 feet to 6 feet, and the length can be cut as needed to meet the needs of most small and medium-sized projects. For special scenarios (such as special-shaped fences, non-standard height protection), Hebei Yangzhe can provide customized services, adjusting the wire diameter, aperture and surface treatment (such as strengthening the galvanized layer) according to the project size and protection strength requirements.

Welded wire mesh: various specifications and welding mesh roll supply

The specifications of welded wire mesh are more abundant. Hebei Yangzhe not only provides standard products with a variety of wire diameters (from fine to coarse) and apertures (from dense to sparse), but also can be customized according to materials (stainless steel, carbon steel, etc.) and surface treatment (galvanized, sprayed). To facilitate transportation and installation, welded wire mesh is often supplied in the form of "welded mesh rolls", and the length can be flexibly adjusted to adapt to the continuous laying requirements of large-scale projects and reduce splicing gaps.

IV. Summary: Choose the right materials to make the project more efficient

Wire mesh (especially galvanized welded mesh and hardware cloth) has the core advantages of corrosion resistance and strong protection, which is suitable for outdoor gardening, breeding protection and other scenes that need to resist natural erosion; welded wire mesh has become the preferred choice for projects such as safety fences, structural support, and decorative grilles due to its uniform structure and stable strength. The differences in the construction process (tight connection vs. welding fusion) and specification characteristics of the two directly determine the scene adaptability.

As a professional wire mesh supplier, Hebei Yangzhe Metal Wire Mesh Co., Ltd. provides a full range of wire mesh and welded wire mesh products, including galvanized welded mesh, hardware cloth, welded mesh rolls, etc., and can provide customized solutions and professional suggestions according to your project needs. Whether you need outdoor anti-corrosion protection nets or indoor and outdoor uniform structure fences, we can help you choose the right materials to ensure the quality and life of the project.

For further product details or customization needs, please contact Hebei Yangzhe and let the professional team escort your project!