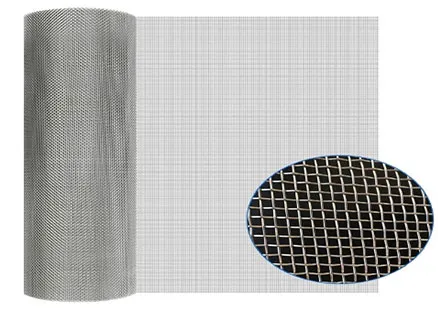

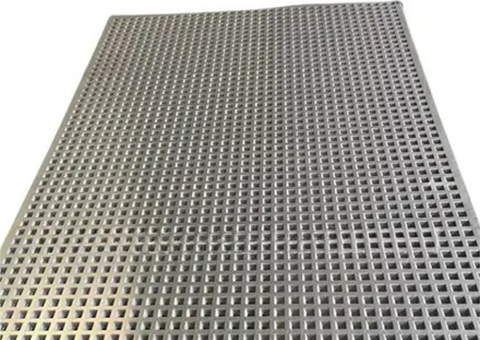

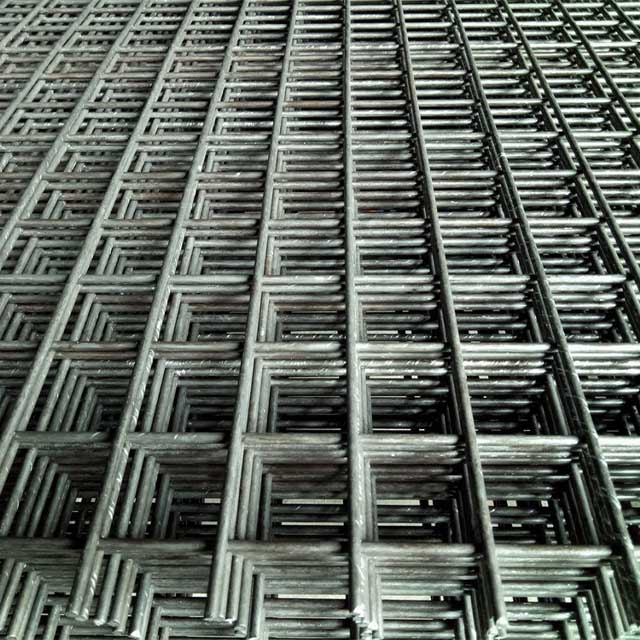

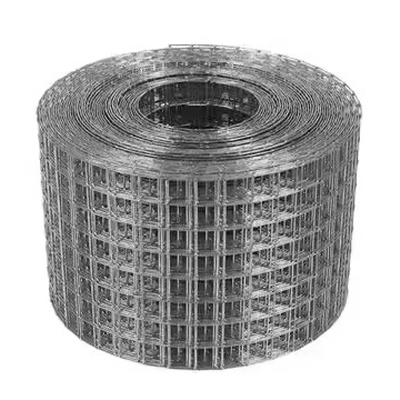

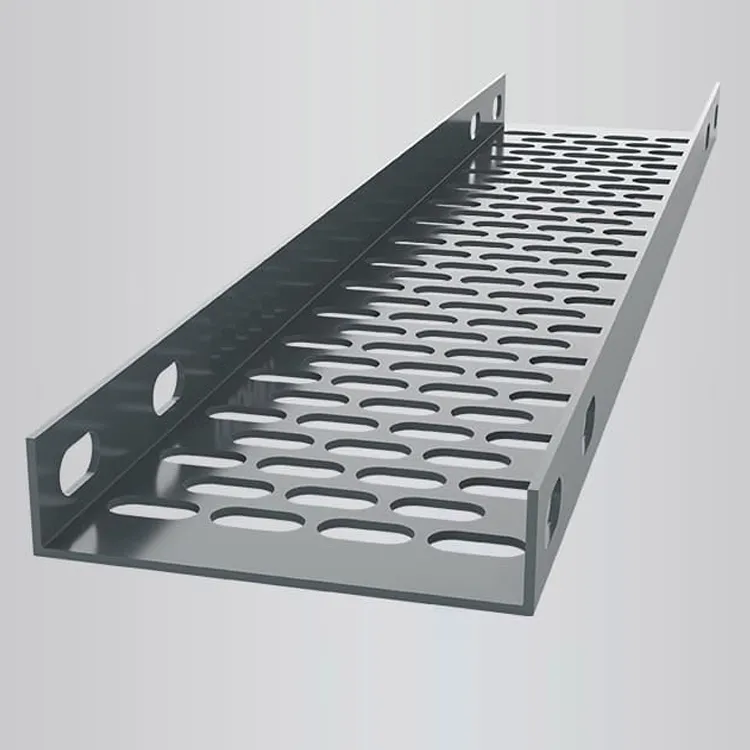

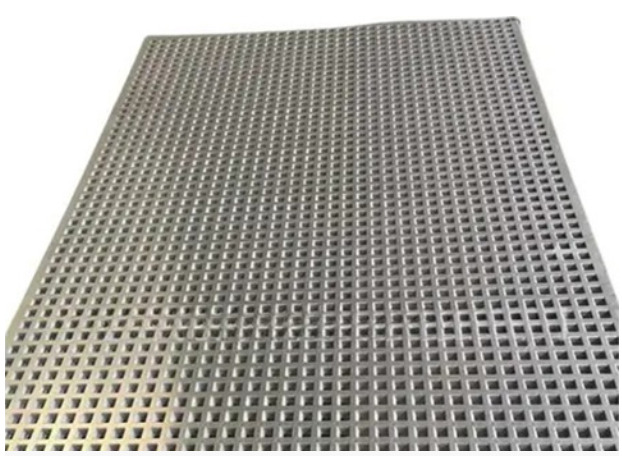

Perforated metal is sheet metal that has been stamped, punched, or sculpted to make a sequence of holes, slots, or ornamental shapes. This manufacturing technique can use a variety of metals, including steel, aluminium, stainless steel, copper, and titanium. Beyond improving the structural appearance of metal, perforating has practical benefits such as increased protection and noise reduction.

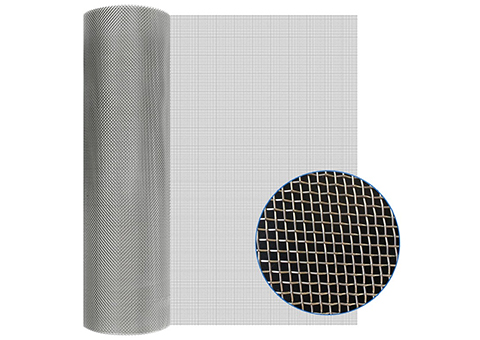

Perforation, traditionally a labour-intensive operation, has been modernised and mechanised to suit today's metal fabrication industry standards. Three methods for making perforated panels include punch press, rotary pin, and laser cutting. They are the basis of current perforated sheet metal fabrication. These technologies enable the high-volume, precise, and customisable manufacture of a perforated metal sheet utilised in a wide range of industries, including architecture, filtration, acoustics, HVAC, and automotive engineering.

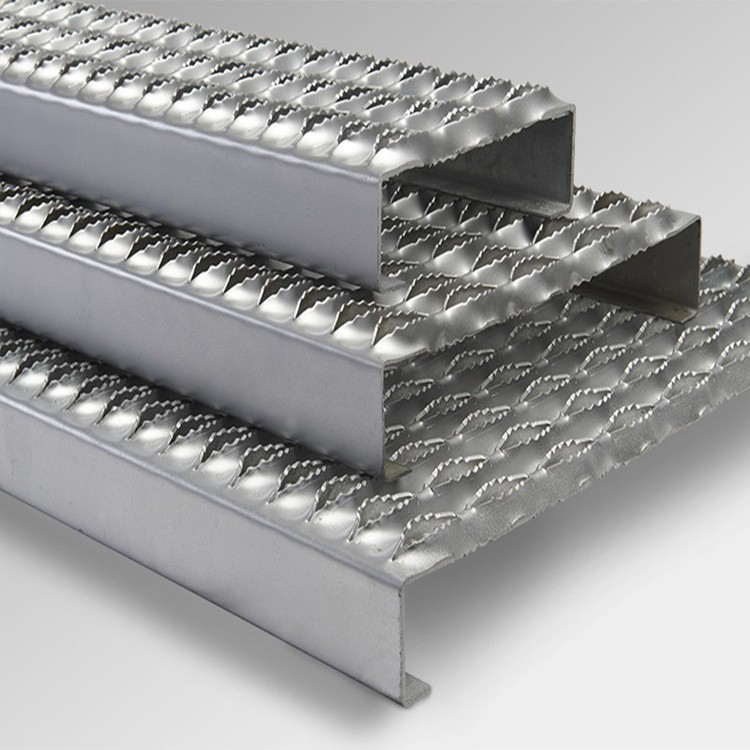

The metal to perforate is determined by factors such as size, gauge thickness, material type, and intended usage. The range of conceivable shapes is incredibly diverse, including circular holes, square cut-outs, slotted patterns, hexagonal designs, and more.

Considerations for Purchasing Perforated Metal Sheets

When purchasing perforated sheet metal, it is critical to evaluate your project's specific needs in order to achieve optimal performance and cost effectiveness. Material type, gauge (thickness), pattern type, open area percentage, and any post-processing requirements like finishing or surface treatments are all important considerations. Confirm the supplier's ability to fabricate exactly bespoke solutions, accommodate short lead times, support big production runs, and meet industry certifications for quality management systems. Choosing the best product for architectural, industrial, or speciality applications is made simpler for customers by the numerous trustworthy perforated metal manufacturers who provide design consulting, prototyping, in-house engineering, and logistics assistance.

Make sure to talk to your manufacturer about your unique performance characteristics, such as sound absorption ratings, airflow rates, strength needs, or goal weight, if you're looking to improve acoustic qualities, airflow, or filtration. A solution that surpasses the functional, aesthetic, and regulatory requirements of your project is guaranteed when engineers, designers, and fabricators work together.

In brief

Buyers and designers may choose the best perforated metal sheet solution for their applications with confidence if they are aware of the vast variety of perforation techniques and secondary finishing procedures. From architectural screens and sunshades to industrial filters and protective guards, using the proper manufacturing procedure ensures high-quality, custom-fit perforated metal products that are both visually appealing and work exceptionally well. Request a quote or connect with a reputable perforated metal supplier to go over your project's specifications and learn how modern perforation technology can help make your design vision a reality.

EN

EN