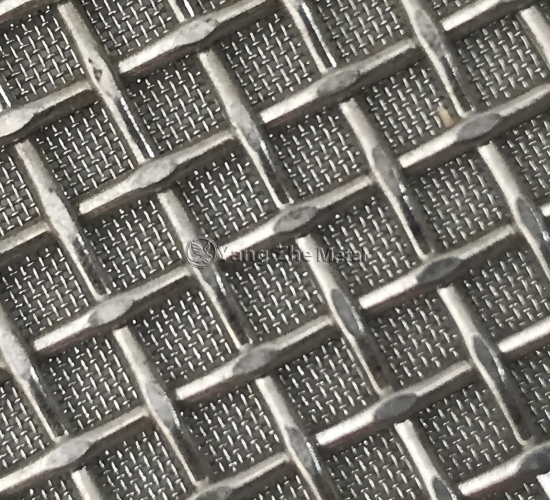

Hebei Yangzhe Metal Wire Mesh Co., Ltd. provides high-performance 316L stainless steel woven mesh, stainless steel woven mesh and 100 200 300 400 micron stainless steel wire mesh cloth, designed for harsh environments such as marine, oil and gas, and chemical industries, ensuring excellent corrosion resistance, durability and cost-effectiveness.

In industries where equipment is exposed to extreme environments, material selection is critical. Whether it is the high salt mist air on offshore oil platforms or the corrosive chemicals in processing facilities, the performance of different materials varies significantly. Stainless steel woven mesh has become the preferred reliable and cost-effective solution for harsh industrial environments such as marine, oil and gas, and chemical processing due to its excellent corrosion resistance, excellent strength and long-term performance. This article is analyzed by Hebei Yangzhe Metal Wire Mesh Co., Ltd. for you.

The core reason why stainless steel woven mesh is popular in harsh industrial environments is its extraordinary corrosion resistance. Unlike ordinary carbon steel or lower-grade alloys, stainless steel contains chromium, which forms a passive protective layer that resists oxidation. This makes it particularly good in environments with high humidity, seawater attack, or frequent chemical contact.

Marine applications: Equipment is often exposed to salt, humidity, and temperature fluctuations. Corrosion-resistant wire mesh made of materials such as 316L stainless steel woven mesh is more durable than other materials, significantly reducing the risk of rust and material degradation.

Chemical applications: Acidic vapors and corrosive compounds can quickly attack fragile materials. Stainless steel woven mesh (especially 316L grade) can ensure stable operation of equipment and provide peace of mind.

The excellent durability of stainless steel woven mesh is another major advantage. It can maintain structural integrity under mechanical stress and temperature changes. This is crucial in applications such as oil rigs and ships, where the mesh may be subjected to constant vibration, pressure changes, and debris impact.

Even after years of use, the high-quality stainless steel industrial woven mesh produced by Hebei Yangzhe Metal Wire Mesh Co., Ltd. is not easy to deform, crack or become brittle. Its tensile strength and abrasion resistance allow it to perform reliably and continuously in critical filtration, separation or shielding applications. In industries where there is no room for error, stainless steel mesh provides the durability needed to maintain smooth operations.

While the initial cost of stainless steel mesh may be higher than some alternative materials, the long-term cost savings are unquestionable. Its long service life means less frequent replacements, less maintenance downtime, and lower labor costs for repairs or installations. In corrosive or high-stress environments, cheaper materials often fail prematurely, leading to frequent maintenance and huge unplanned expenses.

For companies operating in remote areas or offshore, being able to install industrial mesh once and have it perform reliably for a long time is a huge advantage. By investing in corrosion-resistant stainless steel mesh from the beginning, companies can reduce their total cost of ownership and improve overall system reliability.

Stainless steel mesh has a wide range of applications in many harsh environments:

Offshore oil platforms: Used as filter media, protective barriers and reinforcement materials. Its ability to withstand extreme pressures, salts and temperatures makes it an ideal choice for maintaining safe and efficient operations.

Marine Equipment: Commonly used in filters, air intake screens, exhaust systems and protective covers. It helps prevent debris accumulation and equipment damage while providing long-term resistance to seawater corrosion (especially 316L stainless steel mesh).

Chemical Plants/Refineries: Benefit from the excellent performance of stainless steel mesh. It is used in catalyst support systems, drying trays and containment units, which are often exposed to strong acids or high temperatures. Because stainless steel mesh (especially 316L grades) will not degrade in harsh chemical environments, it plays a vital role in ensuring process consistency and plant safety. For fine filtration, 100, 200, 300, 400 micron stainless steel mesh cloth is often selected.

Not all stainless steel mesh is the same. It is critical to choose the right grade for your application. Common stainless steel grades, such as 304 and 316L, offer different advantages.

304 stainless steel: Very resistant to oxidation, suitable for most industrial environments.

316L Stainless Steel: Hebei Yangzhe Metal Wire Mesh Co., Ltd. recommends it for harsh environments. It reduces the carbon content (L) on the basis of 316 and adds molybdenum to provide stronger resistance to chloride corrosion (such as seawater, deicing salt), making it a better choice for marine or highly corrosive chemical environments.

At Hebei Yangzhe Metal Wire Mesh Co., Ltd., we work closely with our customers to determine the best stainless steel woven mesh material (such as 316L stainless steel woven mesh) and weaving method based on the specific requirements of each project (including the required filtration accuracy, such as 100, 200, 300, 400 microns). Our team ensures that each product is carefully designed to meet the specific performance and environmental requirements of your industry.

Stainless steel woven mesh (especially 316L stainless steel woven mesh) is undoubtedly the best choice to protect equipment and maintain operational efficiency in harsh environments. Its excellent corrosion resistance, long-lasting durability and significant cost-effectiveness make it an indispensable and wise investment in key industrial fields.

Whether it is for new offshore platform equipment or upgrading refinery components, choosing the right industrial woven mesh is critical. Hebei Yangzhe Metal Wire Mesh Co., Ltd. is committed to providing high-performance 316L stainless steel woven mesh, stainless steel woven mesh and precision 100 200 300 400 micron stainless steel wire mesh cloth to help you meet the most demanding challenges and improve operational reliability and efficiency.

Contact Hebei Yangzhe Metal Wire Mesh Co., Ltd. now to get customized stainless steel woven mesh solutions that meet your extreme environment needs!