In numerous fields, including industrial manufacturing, precision filtration, and safety protection, woven wire mesh is a fundamental yet crucial engineering material. Its performance directly impacts the efficiency and safety of the entire system. However, many customers often encounter various issues during the selection and use process. As a professional woven wire mesh manufacturer and supplier, [Your Company Name] is well aware of these pain points. This article will provide a comprehensive explanation of woven wire mesh, from the basics to in-depth applications, and answer the most common customer questions.

Woven wire mesh, also known as wire cloth, is a mesh-like material made of metal wires (such as stainless steel, mild steel, copper, and aluminum) woven using precision weaving machinery, interlaced in a specific warp and weft pattern. It's far more than just "wire mesh"; it's a high-performance industrial product with precise apertures, high strength, corrosion resistance, and high-temperature resistance.

Woven Wire Mesh Explained:

Wire Diameter: The diameter of the wire directly affects the strength and durability of the mesh.

Mesh size: The center-to-center distance between two adjacent warp or weft wires determines the size of particles screened or filtered.

Mesh count: The number of mesh holes per inch, a common indicator of filtration accuracy.

Choosing the right weave is the first step to ensuring a successful application. Here are some of the most common types:

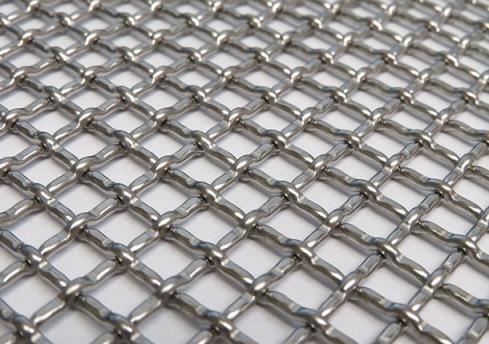

1. Plain Weave

Features: The most common and economical weave, with warp and weft wires woven alternately up and down, providing a stable structure and square mesh.

Applications: General screening and filtration, suitable for most applications that don't require extremely high precision.

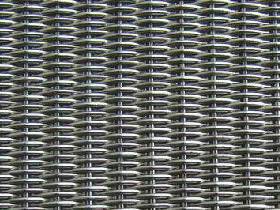

2. Twill Weave

Features: Each warp wire crosses two weft wires, creating a diagonal texture. This structure allows for the use of thicker wire diameters to create smaller mesh openings, resulting in greater strength.

Applications: Heavy-duty screening, high-pressure filtration, mining screens.

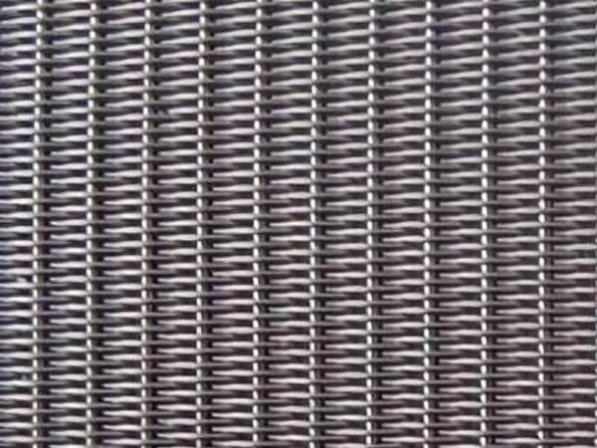

3 Dutch Weave

Features: The weft yarns are much thicker than the warp yarns, forming tapered or wedge-shaped mesh holes with a smooth surface, high filtration accuracy, and resistance to clogging.

Applications: Fine filtration, high-pressure differential environments, slurry filtration.

1. Lisa: "I need to filter/screen particles of a specific size. How should I choose the mesh size and mesh count?"

Yangzhe Metal: This is a core question regarding filtration accuracy. You need to clearly define the target particle size. We recommend:

Precise Measurement: Determine the maximum particle size you need to retain.

Inform our technical engineers of your requirements. We will recommend the most appropriate mesh size and weave based on the characteristics of your particles (e.g., clogging susceptibility, stickiness). For example, a mat weave is a better choice for clogging-prone materials than a plain weave.

2. Andy: "My work environment is subject to corrosion, high temperatures, and abrasion. Which wire mesh material is the most durable?"

Yangzhe Metal: This depends on the material's corrosion and wear resistance.

Corrosive environments (chemical, food, marine): Stainless steel wire mesh is preferred, particularly 304 or 316 stainless steel, which offer excellent rust and chemical resistance.

High-temperature environments: Stainless steels (such as 304, 321, and 316L) and specialty alloys (such as Inconel) can withstand high temperatures without losing strength.

High-wear environments (mining, crushing): High-carbon steel wire mesh or surface-hardened wear-resistant wire mesh is recommended for longer life.

3. Monica: "Why does the wire mesh I bought deform or break easily?"

Yangzhe Metal: This is usually caused by an improper match between the wire diameter and mesh size, or insufficient material strength.

Insufficient strength: In applications where the mesh needs to withstand high pressure or impact, you may need to choose a thicker wire diameter or use a twill weave to increase overall strength.

Improper installation: Improper tensioning can cause the mesh to sag or lead to localized stress concentrations, leading to damage. We can provide professional installation advice tailored to your specific equipment.

4. Lucas: Can I order custom wire mesh in a specific size or shape? "

Yangzhe Metal: Of course! As one of professional custom woven wire screen manufacturers, [your company name]'s core strength lies in providing flexible customization services. Whether it's non-standard widths or roll lengths, or requiring stamping and welding into specific shapes (such as filter discs or baskets), we can precisely manufacture according to your drawings or specifications.

Screening and Grading: Mining, Metallurgy, Building Materials, and Grain Processing.

Filtration and Purification: Petrochemical, Water Treatment, Food and Beverage, and Pharmaceutical Industries.

Safety Protection: Machinery and Equipment Guardrails, Door and Window Security Screens, and Ventilation Masks.

Architectural Decoration: Indoor and Outdoor Curtain Walls, Ceilings, and Railings, Combining Aesthetics and Function.

Reinforcement and Support: Cement Concrete Reinforcement, Composite Material Frameworks, and Catalyst Carriers.

Professional Technical Support: We don't just sell products; we provide solutions. Our team of engineers is happy to assist you with selection and application challenges.

Comprehensive Product Matrix: From economical and practical low-carbon steel wire mesh to high-performance stainless steel wire mesh, we offer a full range of products in various materials, specifications, and weaves.

Strict Quality Control: From raw materials to finished product, every process undergoes rigorous testing to ensure uniform mesh size, precise wire diameter, and long-lasting durability.

Competitive Pricing: As a factory-direct wire mesh supplier, we eliminate middlemen and provide you with the most cost-effective products.

Efficient Customization: We respond quickly to your customization needs and ensure on-time delivery to help your project proceed smoothly.