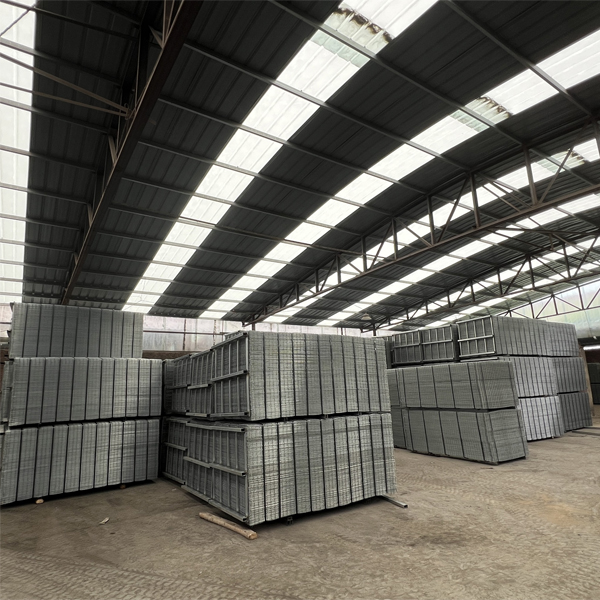

As a senior welded mesh manufacturer, Hebei Yangzhe Metal Wire Mesh Co., Ltd. has been deeply involved in the field of welded wire mesh for many years, focusing on providing high-quality welded mesh, welded mesh and other products to global customers. Welded wire mesh has been widely used in many fields due to its uniform and stable structure, excellent strength and durability. This article will explain in detail the production process and core application scenarios of welded wire mesh, and take you to understand the professional strength of Chinese welded mesh manufacturers.

The high-quality performance of welded wire mesh comes from a rigorous production process. As a standardized welded mesh production factory, Hebei Yangzhe controls the entire process from raw materials to finished products to ensure that each batch of products meets international standards:

1. Raw material processing and wire diameter forming

After hot rolling, the wire rod is drawn to the required diameter through a cold drawing process - during the cold drawing process, the wire rod is gradually reduced in diameter through a series of dies, while improving tensile strength and toughness. According to different application requirements, annealing treatment will be carried out after cold drawing to eliminate internal stress, improve the ductility of steel wire, and lay the foundation for subsequent processing.

The cut steel wire is arranged at a preset spacing on the automatic welding machine, and the longitudinal and transverse steel wires are welded and fixed at the intersection through resistance welding process. Hebei Yangzhe's welding equipment can accurately control the welding current and pressure to ensure that each weld point is firm and does not fall off, forming a grid with uniform spacing and stable structure (such as the aperture error of the welded mesh can be controlled at ≤0.1mm), which is also one of the core technical advantages of Chinese welding mesh manufacturers.

The finished product must undergo strict quality inspection: check key indicators such as dimensional accuracy, welding strength, and surface finish to ensure compliance with industry specifications. In order to improve corrosion resistance, Hebei Yangzhe will galvanize or coat the welded wire mesh (such as PVC, polyethylene coating) to make it rust-proof and anti-aging, suitable for humid, outdoor and other complex environments.

2. Core application scenarios of welded wire mesh: "strength and protection" solutions in multiple fields

As a professional Chinese welding mesh manufacturer, Hebei Yangzhe's welded wire mesh (including electric welded mesh) is suitable for the following core scenarios with its customization advantages:

1. Water filtration system: precision grid ensures filtration efficiency

Welded wire mesh can be made into a filter basket, which can achieve precise filtration with uniform pore size. After anti-corrosion treatment, its surface can withstand water erosion and play a stable role in industrial wastewater treatment, agricultural irrigation filtration and other scenarios. Chinese welding mesh manufacturers can customize electric welded mesh with different pore sizes according to the requirements of filtration accuracy to meet the needs of segmented scenarios.

2. Partitions and fences: a reliable choice for safety protection

The uniform structure and high strength of welded wire mesh make it an ideal material for partitions and fences:

Industrial partitions: Factory workshops and storage areas are divided into areas with welded mesh to ensure orderly production and good air permeability;

Outdoor fences: Community walls and factory boundary fences are made of welded mesh, which is both safe and beautiful, and can be customized in height, wire diameter and surface color;

Gabion wall construction: Rocks and gravel are put into welded mesh baskets to make gabion walls, which are flexible and can adapt to irregular terrain, effectively preventing soil erosion.

3. Animal fences and agricultural fields: durable protection and ecological consideration

Agriculture and breeding scenarios have extremely high requirements for the corrosion resistance and protection of welded wire mesh. Hebei Yangzhe provides targeted solutions:

Breeding fences: Customized welded mesh is used for livestock fences such as chicken houses and cattle pens. The fine mesh prevents animals from escaping. The galvanized or coated treatment ensures that it will not rust in outdoor humid environments;

Crop protection: Agricultural greenhouses and vegetable gardens use welded mesh to block pests, birds and predators to protect crop growth;

Climbing plant support: Welded mesh can be used as a climbing frame for vines, which is both supportive and breathable.

In construction, welded wire mesh is the core material for concrete reinforcement:

Wall and floor reinforcement: The welded mesh is embedded in the concrete to evenly distribute the load, prevent cracks, and improve the overall strength and service life of the structure;

Pavement and foundation reinforcement: The impact resistance of the concrete pavement is enhanced by the welded mesh, which reduces settlement and damage. It is suitable for municipal roads, factory floors and other scenes.

As a professional welded mesh production factory, Hebei Yangzhe can customize reinforcement welded mesh with different wire diameters and apertures according to project requirements to ensure that it meets construction standards.

The industrial environment has strict requirements on material strength and stability, and welded wire mesh performs well in this field:

Conveyor belt system: low-carbon steel welded mesh is used for conveyor belt skeletons, embedded in rubber or composite materials, providing tensile and fracture resistance, and is suitable for bulk material transportation in mining, construction and other industries;

Ventilation and drainage: The mesh design allows air circulation and drainage to avoid material deterioration due to moisture during transportation and ensure production efficiency;

Equipment protection net: welded mesh is used as a protective fence around industrial equipment to prevent accidental contact without affecting equipment heat dissipation.

3. Hebei Yangzhe: The core advantages of China's welding mesh manufacturers

As a powerful electric welding mesh production factory, Hebei Yangzhe has always taken "quality + customization" as the core to create value for customers:

Customization capability: support customized wire diameter, aperture, size, surface treatment (galvanized, PVC coating, etc.) of electric welding mesh according to demand, adapting to the needs of multiple scenarios;

Quality assurance: full process quality inspection + ISO9001 quality system certification, raw materials can provide material certification and traceability report to ensure that the products meet the standards of Europe, America, Australia and other regions;

Stable production capacity: with multiple automated welding equipment, sufficient monthly production capacity, can quickly respond to batch orders and emergency replenishment needs.

Conclusion: Choose a professional Chinese welding mesh manufacturer to ensure the efficient implementation of the project

The diverse applications of welded wire mesh are inseparable from the technical support of professional manufacturers. As a senior electric welding mesh production factory, Hebei Yangzhe Metal Wire Mesh Co., Ltd. empowers the entire process from production process to product application, providing reliable welding mesh solutions for global customers.

Whether you need welded mesh for agricultural protection, welded mesh for construction reinforcement, or customized welded wire mesh for industrial heavy-duty scenarios, Hebei Yangzhe can provide one-stop service. Contact us now to get exclusive customized solutions and experience the professional strength of China's welded mesh manufacturers!