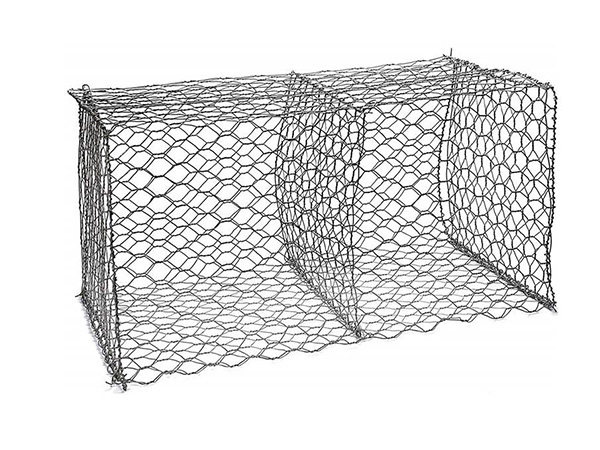

Hebei Yangzhe Metal Products Co., Ltd., as a professional gabion manufacturer, is committed to providing customers with high-quality, durable woven gabion (also known as hexagonal gabion) products and comprehensive engineering solutions. The gabions we produce are made of corrosion-resistant, high-strength high-quality galvanized wire or PVC-coated galvanized wire, and the unique hexagonal mesh structure gives it excellent performance.

The core advantages of Yangzhe woven gabions

Excellent flexibility: Compared with welded gabions, Yangzhe woven gabions are more flexible, can perfectly adapt to terrain changes, and significantly enhance the protection effect.

Convenient and efficient construction: The installation process is simple, which greatly saves construction time and cost.

Economical and reliable: It is an economical, efficient and stable preferred solution in water conservancy, civil engineering and ecological construction.

Wide application areas of Yangzhe woven gabions

Hebei Yangzhe's woven gabions have become the first choice of engineers and project parties due to their flexible and diverse sizes and designs:

Water conservancy projects: river bank protection, dam reinforcement, riverbed regulation, diversion dam construction.

Geological protection: slope stability, rock reinforcement, landslide prevention, mine greening.

Infrastructure: road/railway slope protection, bridge pier protection.

Ecological construction: river ecological restoration, slope vegetation restoration (can be combined with grass planting), gabion retaining wall.

Landscape: landscape retaining wall, flower bed edge, characteristic wall.

Hebei Yangzhe woven gabion professional installation guide (step-by-step explanation)

Safety and stability are the core of gabion engineering. Yangzhe provides you with professional installation guidance, whether it is a large-scale project or a private project, it can ensure the best results.

Step 1: Preparation

Check materials: Count the compressed gabion mesh and matching binding wires provided by Hebei Yangzhe.

Prepare tools: Prepare binding hooks, rulers, micrometers (for spot checking wire diameters), protective gloves, etc. For example, install a 2m x 1m x 1m (mesh wire diameter 2.7mm) gabion box.

Step 2: Unfold the mesh box

Spread the gabion mesh (bottom plate, four side plates, cover plate and middle partition plate) flat.

Step 3: Assemble the mesh box

Collaborative assembly: It is recommended that two people cooperate. One person holds the side plates and partitions steady, and the other person uses tying wire to fix the connection points.

Connection points: Firmly connect the side plates, partitions and bottom plates.

Step 4: Fill with stones

(Important step, see the professional tips below for details)

Step 5: Close the cover plate

After the stones are filled in place, cover the cover plate and fix it tightly with double-strand tying wire of the same specification.

Yangzhe engineers share: 7 must-know professional tips for installing woven gabions

Strictly control material acceptance:

Measure the mesh size and wire diameter (make sure it meets the design, such as 2.7mm) to verify its stability and tensile strength.

Focus on surface treatment: Hebei Yangzhe reminds you that the zinc content and quality of the galvanized layer directly determine the corrosion resistance and service life of the product, so be sure to check carefully.

Secure binding is the key - double-strand binding method:

Cut the binding wire into about 25cm long and fold it in half into two strands.

Pass through the intersection of the two meshes to be connected, and tighten it with a binding hook.

Yangzhe strongly recommends this double-strand binding method! It not only ensures an extremely firm connection, but also effectively speeds up the installation. The mesh connection needs to be tied and fixed every 25cm or so.

Foundation treatment requirements - simplified but not negligible:

Yangzhe advantages: Woven gabion walls usually do not require complex concrete foundations, reducing costs.

Key requirements: It must be placed on a flat, stable, and compacted base! Common practices:

Lay a layer of well-graded gravel cushion and compact it.

Qualified geotextiles can be added for slope protection.

Yangzhe recommends:

Walls with a height of ≤1m: compacted hard foundation of about 10cm thick.

Walls with a height of ≈3m: compacted gravel cushion of 50-100mm thick.

Make sure that the foundation is evenly laid and layered and staggered.

Wall stability and connection:

Adjacent gabions need to be connected to each other along the frame or bottom frame with binding wires to form an integral structure.

Stepped stable design: During construction, each layer of gabions can be slightly tilted backward (about 6-10 degrees) to form a step shape. This structure is more stable than a completely vertical wall.

Efficient filling and compaction techniques:

For large projects, mechanical filling is preferred, supplemented by manual placement and adjustment.

Yangzhe specification:

Each box on the same layer must be filled evenly and synchronously.

The thickness of each filling is ≤30cm.

After each layer is partially filled, stones are placed manually to minimize gaps (large gaps will increase risks!).

It is recommended to fill a 1m high box in 4 times.

The final filling needs to be slightly higher than the box, compacted and flattened to ensure that the stones are tightly bitten, and the remaining gaps are filled with small stones.

Prevent bulging - support reinforcement is essential:

In addition to double-strand binding, Yangzhe strongly recommends installing internal support! Bulging affects the appearance and threatens safety.

During the assembly of the box, cross-bind steel wires between the front and rear and left and right side panels as support to effectively prevent the side panels from bulging outward and ensure the long-term structural strength and shape stability of the wall.

Selected filling stones - Yangzhe quality assurance:

Stone selection standards are crucial! Hebei Yangzhe recommends the use of:

Hard and durable: not easy to weather, no cracks, and resistant to freeze-thaw (permeable rocks are easily weathered and damaged).

Clean: No dirt, rust or other impurities on the surface.

Suitable size: The diameter is generally greater than 20cm (to prevent slipping from the mesh), and the corner stones are better interlocked.

Performance meets the standard: Density > 25kN/m³, compressive strength > 60MPa.

Choose Hebei Yangzhe, choose professionalism and reliability

Hebei Yangzhe Metal Products Co., Ltd. provides high-quality woven gabions (hexagonal gabions) of all specifications, strictly controls raw materials and production processes, and ensures high strength, long life and strong corrosion resistance of products. We not only provide products, but also provide professional technical consultation and installation guidance. We are your solid partner for water conservancy projects, slope protection, ecological management and landscape projects.