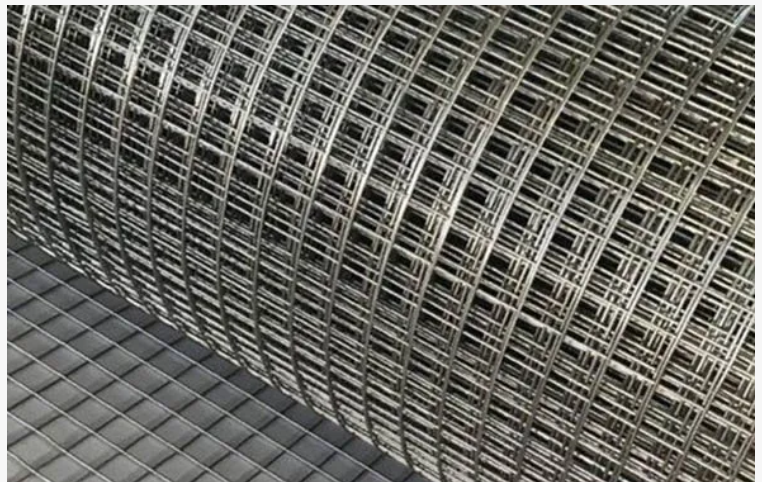

Welded steel wire mesh is a grid-like structure made up of intersecting steel wires welded together at each junction point to generate a consistent and stable pattern. This mesh can be made in a variety of sizes and configurations to meet individual requirements and applications. Wire rods are pulled through a sequence of dies to decrease their diameter to the specified thickness.

The cut wires are arranged on a welding machine in a grid pattern. The machine joins the cables at junctions using automatic electric resistance welding. This includes applying pressure and delivering an electric current via the contact points, causing the wires to heat and fuse. The end result is a robust, durable welded wire mesh with exact spacing.

After being cold-drawn, the wire rod is annealed to reduce internal tensions and increase ductility.

Once the steel wire rod has been hot rolled, cold drawn, and annealed, it is ready for the last stages of wire manufacture.

This could include bending the wire into different shapes, such as mesh, woven wire fabric, or spiral-wound wire.

Finally, the steel wire is coated with PVC or polyethylene to improve corrosion resistance and increase lifespan.

Welded steel wire mesh is used to produce industrial barriers and enclosures that improve production safety and organisation.

Its adaptability and customisable possibilities enable it to meet specific industry requirements.

Workers load wire mesh baskets with pebbles, gravel, or other materials to build gabion walls, which are well-known for their flexibility and ability to adjust to irregular shapes and so restrict erosion.

Welded steel wire mesh is used in animal husbandry to create sturdy and secure enclosures for cattle, assuring their safety and well-being.

Crop protection, climbing plant support systems, and pest and predator fencing all make use of welded steel wire mesh.

When galvanised or coated, steel wire rod mesh is rust-resistant.

Welded wire mesh is often used to reinforce concrete structures, increasing load-bearing capacity and overall strength. Welded wire mesh in walls and floors helps distribute loads evenly and minimise structural flaws, assuring long-term durability. Welded wire mesh reinforces concrete, preventing the creation of cracks and other structural flaws and ensuring the construction's integrity.

In industrial contexts, mild steel welded wire mesh is utilised to carry commodities via conveyor belt systems.

Steel wire rods are pulled into wire and then utilised to form steel cords or strands. These cords or strands are inserted in the conveyor belt's rubber or other material to increase strength, durability, and resistance to straining and breaking.

This reinforcement is essential in conveyor belts used in the mining, construction, and bulk material handling industries.

Steel wire rods for various applications require certain mechanical qualities such as tensile strength, yield strength, ductility, and elasticity. Automotive, aerospace, and medical device industries all have stringent regulations governing material qualities, quality standards, and certifications. When selecting the appropriate type of steel wire rod, keep the intended use, performance requirements, environmental concerns, and regulatory standards in mind.